Eagleview

Veteran Member

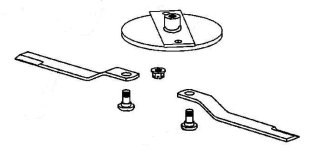

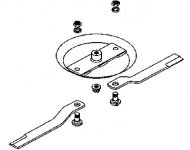

I bought a new slasher to do large areas quickly as some people do'nt require the better finish that my flail mowers leave . So i shelled out $6000 on a new "Kanga" slasher , being a well known brand in OZ . After an hour i got the spanners out to check all the bolts and noticed oil running out the bottom gearbox seal . The castleated nut had come loose and the cutter bar was about to cut my tractor tyres off . After pulling it apart i was amazed at how badly the cutter bar flange was made . They had cut off a piece of 5"X5/8" flat bar in the guilotine . Which left the ends out of true . They then cut out the center hole with a hand held oxy torch which left it jaggered and not centered , drilled the two 5/8" holes off center and then butt welded this mess onto the splined hub which pulled the plate into an arc with the cooling welds and did not true it back up in a lathe or mill . This then caused the cutter bar to be bent with the bolts untill it seated on the plate putting the bolts under great strain just to do this which left the bar loose (look at the fret marks where the bar has been moving). And then because the 1/4" split pin hole was high in the splined hub , they could not get a 1/4" split pin in the hole so they bent an 1/8" one into a fish hook shape and threaded that in . Needless to say the nut could undo about 5 degrees before the pin could stop it which then made the spline work loose . I phoned "Kanga Slashers" and told them i could not believe that they would build a critical component so badly . I said the plate should have been counter bored and the splined hub should have been turned down and press fitted into it before being welded and then the face of the plate trued up after the welds cooled . He said that's how they do it . Have a look at the mill scale on the "machined" plate and the thickness of the plate at both places were they "did" counter bore it . I am now building my own slasher , at least i know it will be done right . I will also be machining a "well" into the flange that the cutter bar will sit in so that the bolts only hold it up and not take the shear forces that the ones in the photos do (which are metric in a 5/8" hole , loose to start with).