rambler

Veteran Member

- Joined

- Jul 6, 2003

- Messages

- 1,992

- Location

- MN

- Tractor

- Ford 960, 7700, TW20, 1720; IHC H, 300; Ollie S77

A company in Florida selling something to blade snow???? That always leads to fun results.  Not for the owner of the new gizzmo, but for those seeing the results.

Not for the owner of the new gizzmo, but for those seeing the results.

You will drive over to your dad's place at under 5 mph? That will last maybe 1/2 of one trip, then you'll be at 60mph like everyone else.

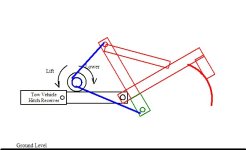

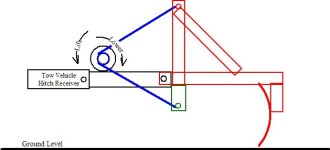

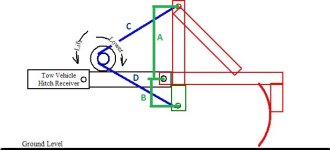

Looks like a nifty idea, but also a way to really break up some equipment in a hurry.

I kinda like the garden tractor converter, that will work until the tractor spins out, not much broken. The pickup hitch - well nifty looking, but the potential to bust things is high, and it can't possibly be road legal so don't have an accident.....

Just sayin'.

--->Paul

You will drive over to your dad's place at under 5 mph? That will last maybe 1/2 of one trip, then you'll be at 60mph like everyone else.

Looks like a nifty idea, but also a way to really break up some equipment in a hurry.

I kinda like the garden tractor converter, that will work until the tractor spins out, not much broken. The pickup hitch - well nifty looking, but the potential to bust things is high, and it can't possibly be road legal so don't have an accident.....

Just sayin'.

--->Paul