DavidVT

Gold Member

Hello,

Looking for ways to beef up my RB84 rear blade.

This is used mostly for snow removal and the majority of the time I push the blade in reverse with the cutting edge facing forwards. The idea is to ride up on obstructions rather than catch them.. It usually works....

This winter the blade has not worked that hard (mild winter in Vermont), but the damages are starting to really accelerate.

Last summer the primary pivot bolt (used to angle the blade R to L) backed out of the welded nut and both the bolt and nut were a total loss. Fortunately I was able to insert a similar size bolt and fasten it with a large lock nut. I accept responsibility for not checking the bolt was getting loose.

A few months ago the tilt pivot (used to level or lower one side of the blade to cut a ditch) was completely split. No idea why but I was able to dig out the new welder and pour enough rod into it to make is stay together. (proud of that fix but it looks pretty novice). I suspect a poor weld from when it was put together. When that failed, it allowed the blade to hang off the frame by the tilt pivot pin. That is why the photos will show that rear most pin at an odd angle.

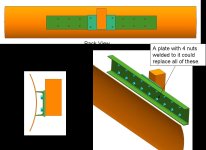

Two days ago I noticed the blade at an odd angle and thought the above weld might have failed. No such luck. The blade is bolted near the hub to a square plate. Four bolts hold the 84" blade to the plate. This plate is welded to the tilt pivot assembly. The bottom side of the plate split, allowing the plate to flex as the blade caught snow on one side or the other.

Today I inspected the area and discovered this new split. Curiously I found a repaired split on the other side in exactly the same place. Maybe this is OEM?

Anyone with a Woods RB84, please tell me if you find vertical welds between the two middle lower blade mount bolts. The welds will be below this tilt pivot tube and on the plate with the 4 mounting bolts.

SO, anyone have a good idea how I can beef this up enough to survive a few more years?

Thank you!

Looking for ways to beef up my RB84 rear blade.

This is used mostly for snow removal and the majority of the time I push the blade in reverse with the cutting edge facing forwards. The idea is to ride up on obstructions rather than catch them.. It usually works....

This winter the blade has not worked that hard (mild winter in Vermont), but the damages are starting to really accelerate.

Last summer the primary pivot bolt (used to angle the blade R to L) backed out of the welded nut and both the bolt and nut were a total loss. Fortunately I was able to insert a similar size bolt and fasten it with a large lock nut. I accept responsibility for not checking the bolt was getting loose.

A few months ago the tilt pivot (used to level or lower one side of the blade to cut a ditch) was completely split. No idea why but I was able to dig out the new welder and pour enough rod into it to make is stay together. (proud of that fix but it looks pretty novice). I suspect a poor weld from when it was put together. When that failed, it allowed the blade to hang off the frame by the tilt pivot pin. That is why the photos will show that rear most pin at an odd angle.

Two days ago I noticed the blade at an odd angle and thought the above weld might have failed. No such luck. The blade is bolted near the hub to a square plate. Four bolts hold the 84" blade to the plate. This plate is welded to the tilt pivot assembly. The bottom side of the plate split, allowing the plate to flex as the blade caught snow on one side or the other.

Today I inspected the area and discovered this new split. Curiously I found a repaired split on the other side in exactly the same place. Maybe this is OEM?

Anyone with a Woods RB84, please tell me if you find vertical welds between the two middle lower blade mount bolts. The welds will be below this tilt pivot tube and on the plate with the 4 mounting bolts.

SO, anyone have a good idea how I can beef this up enough to survive a few more years?

Thank you!