Mr Super Hunky

New member

- Joined

- Aug 20, 2010

- Messages

- 14

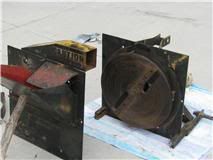

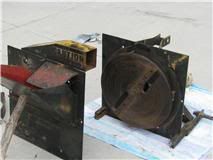

I recently purchased this old chipper from a neighbor who knows nothing about it. Neither do I.

I hooked it up the PTO behind my 48hp Massey and it worked fine other than I discovered it has a broken blade and a broken anvil.

It is a direct drive shaft right off the pto with NO gear reduction and thus it only spins as fast as my pto will turn.

The original color of the unit appears to be industrial yellow. It has a 17 7/8 inch diameter flywheel that weighs around 100 lbs (guessing). It does not appear to have too many safety features. Actually, it has none!

While my tractors hp is plenty powerfull, I must run the engines rpm's at around 2,500 for the flywheel to spin fast enough (NO gear reduction), but at that speed it seems to chip great.

Has anyone seen an old chipper like this before?, if so I'd like your opinion as to what this may be. There is nothing written on it anywhere other than having a Bondioli & Pavesi driveshaft.

Thanks in advance for your input.

BTW, I paid $150 bucks for it. It's not a Wallenstein BX62 but it was $150 bucks!

When it comes to money, I get weak!!

I hooked it up the PTO behind my 48hp Massey and it worked fine other than I discovered it has a broken blade and a broken anvil.

It is a direct drive shaft right off the pto with NO gear reduction and thus it only spins as fast as my pto will turn.

The original color of the unit appears to be industrial yellow. It has a 17 7/8 inch diameter flywheel that weighs around 100 lbs (guessing). It does not appear to have too many safety features. Actually, it has none!

While my tractors hp is plenty powerfull, I must run the engines rpm's at around 2,500 for the flywheel to spin fast enough (NO gear reduction), but at that speed it seems to chip great.

Has anyone seen an old chipper like this before?, if so I'd like your opinion as to what this may be. There is nothing written on it anywhere other than having a Bondioli & Pavesi driveshaft.

Thanks in advance for your input.

BTW, I paid $150 bucks for it. It's not a Wallenstein BX62 but it was $150 bucks!

When it comes to money, I get weak!!