picker77

Gold Member

- Joined

- Feb 4, 2006

- Messages

- 385

- Location

- Central Oklahoma

- Tractor

- JD 3032E, dual remotes, TnT, tooth bar, grapple

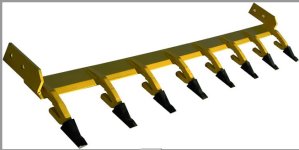

I have a set of Chris Perry's JDQA forks coming, and the only other "major" attachment I am considering for my new 3032E is a tooth bar. In doing my homework on these things, I noticed most seem to follow a common design with the support bar above the bucket lip, with each tooth hooked underneath for support. All of the ones I looked at use essentially the same replaceable tooth design, and they all are probably equally strong as far as the actual teeth go. Having never used a tooth bar before, I'm wondering if this design causes a pronounced grooving effect from the teeth when back-dragging with the bucket, and if it might also make it difficult to avoid unwanted surface damage when scooping up stuff from smooth areas. The first three photos, all of this common design, are the current Dirt Works, Gator (Markham), and Iowa Farm Equipment versions.

However, in the fourth photo, Long seems to have taken a somewhat different approach, and at first glance it seems to make more sense to me. They put the heavy support bar UNDER the bucket lip, making the bottom surface of the teeth level with the bottom surface of the support bar. With this design, I should be able to back-drag and leave a perfectly smooth surface behind, and also scoop stuff up from smooth areas without grooving damage. In addition, on all the other designs I've seen the bucket's original edge is still exposed to wear, but with Long's version the tooth bar's beveled edge takes the brunt of the force and wear when digging, not the bucket edge.

Would some current owners of Long tooth bars (and other brands, for that matter) please comment on whether I'm correct in my thinking on this? All of these bars fall in the same general range, so my choice will be driven by design and usefulness, not price.

However, in the fourth photo, Long seems to have taken a somewhat different approach, and at first glance it seems to make more sense to me. They put the heavy support bar UNDER the bucket lip, making the bottom surface of the teeth level with the bottom surface of the support bar. With this design, I should be able to back-drag and leave a perfectly smooth surface behind, and also scoop stuff up from smooth areas without grooving damage. In addition, on all the other designs I've seen the bucket's original edge is still exposed to wear, but with Long's version the tooth bar's beveled edge takes the brunt of the force and wear when digging, not the bucket edge.

Would some current owners of Long tooth bars (and other brands, for that matter) please comment on whether I'm correct in my thinking on this? All of these bars fall in the same general range, so my choice will be driven by design and usefulness, not price.