dholly

Platinum Member

Howdy, looking for some input on a project here. Feel free to take a crack at one or more.

I picked up an Olathe model 67 leaf blower that was originally a front mount accessory for a Toro Groundsmaster, thinking it might be easy enough to mod for 3-pt hitch use. Unfortunately, it is off a 72 Series not a 52 or 62 Series, more on that later. In any event, I see some 'issues' so before I get started I figure I'd ask a couple questions. Surely someone has already done this.

Issue #1- Blower was designed to run at 1850 rpm straight off the Groundsmaster 72 front PTO shaft so I'll need to make a speed increaser. I'm leaning towards pulley and belts vs. sprocket and chain. If no arguments to the contrary, what size (width) single or dual belts would be appropriate for this application?

Issue #2 - Run blower at 540 or 960 rpm rear PTO speed? Keep in mind, my B7610 rear and mid PTOs are not independent. You can't run the mid PTO at 2500 rpm with the rear PTO being dead, and you can't run the rear PTO at 960 rpm w/o the mid PTO being live. When the lever is at the center position, both PTO's are dead. With the lever at the rear position, the rear PTO is running at 540 rpm and the mid is dead. When the lever is in the forward position, the mid PTO is running at 2500 rpm and the rear is running at 960 rpm. This will come into play if I want to mount the blower to my 3-pt hitch and use simultaneously with the belly mower. Ie., if I gear the increaser for 960 PTO speed (the only speed at the rear PTO when the belly mower is operating), in the event I just want to use the blower only it will be run at 540 PTO speed and lose almost 50% blower efficiency. While running both at once sounds good in theory, in reality do you think there's any value in the idea of dual use or just gear the increaser for 540 PTO speed and run the blower alone?

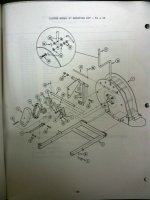

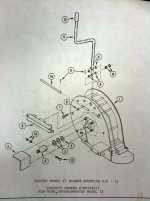

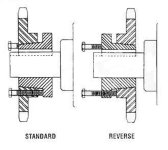

Issue #3 - Any source for (defunc) Olathe blower parts, maybe Toro Turf dealers? The Groundsmaster Series 52 and 62 mounting kit for the Olathe 67 blower is different than the mounting kit for the Groundsmaster Series 72 (pics 1 and 2 respectively). If I could find the increaser system parts used for the GM Series 52/62 it might make life easier. I believe the Olathe Model 61 blower (the Olathe factory 3-pt blower, see pic 3) also used this system. Alternatively, maybe a replacement PTO stub in pillow block bearings for the lower pulley and PTO shaft connection... ? Suggestions welcomed.

Issue #4 - Replacement bearings. Best I can tell the main bearings are Hub City FB250x1-1/4 four bolt flange bearings. There's a manufacturer cross reference on their website however, not being a bearing aficionado, it did little more than confuse me. Does any particular replacement bearing maker (for quality) and source (best pricing) come recommended? Might need to pick up some pillow block bearings too as mentioned in the previous paragraph, best to source together for shipping I suspect.

Issue #5 - Wheels front or behind? As it was, wheels were in front (pic 4) but they will be in back on the 3-pt and I wonder if the lower front edge of the housing will now catch and gouge on uneven terrain? Would you cut 'em off and reweld to the front or leave as is and add a roller to the front edge? Or not even bother.

Well that's enough for now, off to tear it down and clean things up. I think I have some Kubota orange somewhere in the paint box to use up. :thumbsup:

I picked up an Olathe model 67 leaf blower that was originally a front mount accessory for a Toro Groundsmaster, thinking it might be easy enough to mod for 3-pt hitch use. Unfortunately, it is off a 72 Series not a 52 or 62 Series, more on that later. In any event, I see some 'issues' so before I get started I figure I'd ask a couple questions. Surely someone has already done this.

Issue #1- Blower was designed to run at 1850 rpm straight off the Groundsmaster 72 front PTO shaft so I'll need to make a speed increaser. I'm leaning towards pulley and belts vs. sprocket and chain. If no arguments to the contrary, what size (width) single or dual belts would be appropriate for this application?

Issue #2 - Run blower at 540 or 960 rpm rear PTO speed? Keep in mind, my B7610 rear and mid PTOs are not independent. You can't run the mid PTO at 2500 rpm with the rear PTO being dead, and you can't run the rear PTO at 960 rpm w/o the mid PTO being live. When the lever is at the center position, both PTO's are dead. With the lever at the rear position, the rear PTO is running at 540 rpm and the mid is dead. When the lever is in the forward position, the mid PTO is running at 2500 rpm and the rear is running at 960 rpm. This will come into play if I want to mount the blower to my 3-pt hitch and use simultaneously with the belly mower. Ie., if I gear the increaser for 960 PTO speed (the only speed at the rear PTO when the belly mower is operating), in the event I just want to use the blower only it will be run at 540 PTO speed and lose almost 50% blower efficiency. While running both at once sounds good in theory, in reality do you think there's any value in the idea of dual use or just gear the increaser for 540 PTO speed and run the blower alone?

Issue #3 - Any source for (defunc) Olathe blower parts, maybe Toro Turf dealers? The Groundsmaster Series 52 and 62 mounting kit for the Olathe 67 blower is different than the mounting kit for the Groundsmaster Series 72 (pics 1 and 2 respectively). If I could find the increaser system parts used for the GM Series 52/62 it might make life easier. I believe the Olathe Model 61 blower (the Olathe factory 3-pt blower, see pic 3) also used this system. Alternatively, maybe a replacement PTO stub in pillow block bearings for the lower pulley and PTO shaft connection... ? Suggestions welcomed.

Issue #4 - Replacement bearings. Best I can tell the main bearings are Hub City FB250x1-1/4 four bolt flange bearings. There's a manufacturer cross reference on their website however, not being a bearing aficionado, it did little more than confuse me. Does any particular replacement bearing maker (for quality) and source (best pricing) come recommended? Might need to pick up some pillow block bearings too as mentioned in the previous paragraph, best to source together for shipping I suspect.

Issue #5 - Wheels front or behind? As it was, wheels were in front (pic 4) but they will be in back on the 3-pt and I wonder if the lower front edge of the housing will now catch and gouge on uneven terrain? Would you cut 'em off and reweld to the front or leave as is and add a roller to the front edge? Or not even bother.

Well that's enough for now, off to tear it down and clean things up. I think I have some Kubota orange somewhere in the paint box to use up. :thumbsup:

Attachments

Last edited: