KennyG

Elite Member

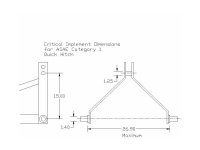

I have a question for you guys. My wife bought me HF quick hitch and I am having problems, it appears the hooks where the pins from my rototiller and brush hog sit in are too wide and I was wondering if I could cut them down some to make it work I like the ability to just back up and hook up and go but I cant do that presently :-(

A picture or a little more explanation might help. Does it appear that the hooks on the quick hitch would have to be closer together or farther apart for the attachments to fit? Do the attachments have cantilever pins (threaded pin bolted into a hole) or through pins (pin floating through holes on two separated plates)?