Building hydraulic gauge wheel on a Landpride RBT heavy duty rear blad

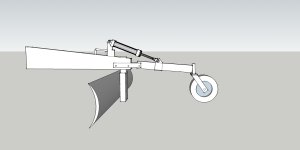

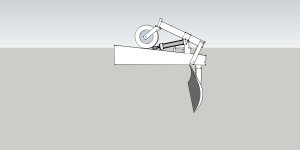

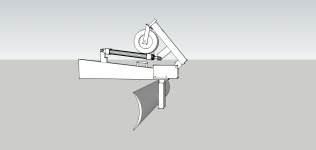

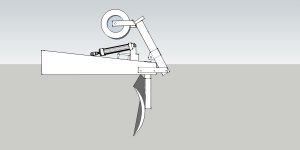

Here is where I'm at so far...

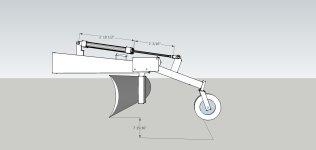

..which is pretty similar to Landprides gauge wheel option on the RBT 45 series, like this one.

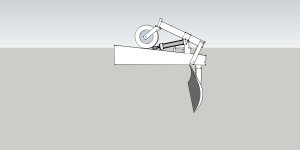

The "geometry" seems a bit difficult for someone like myself to figure out...or rather, make it work, to the point where I can completely raise and "store" the gauge wheel up out of the way, so I'm thinking about making it so I can easily disconnect the cylinder, fold it back, and then fold the gauge wheel back in case I need to.

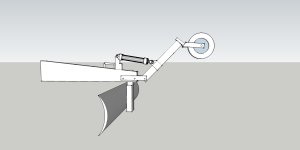

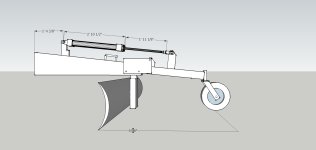

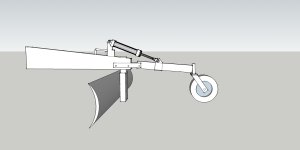

This is roughly what it would look like with the cylinder retracted.

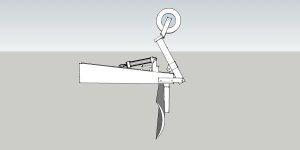

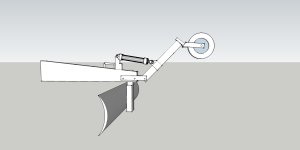

Then if I wanted to get it up out of the way, for instance if I was working in the woods and the additional length was an issue, I could disconnect the cylinder on one end and fold it back. I'd have to make sure I had enough clearance for the 90 degree fittings not to bottom out on the blade frame.

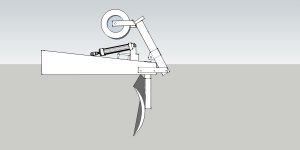

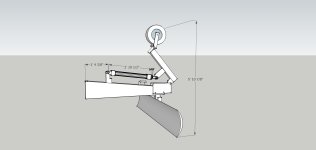

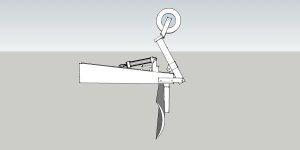

I'm thinking I could either make a bracket to fix it in this position, or, if I wanted it to be more "compact", and not stick way up in the air, I could flip the gauge wheel around, and remove one of the bracket pins, and fold the rest of the assembly up and back over itself.

I'm not sure how viable these ideas are, do you guys have any thoughts as to if this would work or not? Or am I 'over designing' an otherwise simple thing?