leonz

Super Member

Good afternoon to my fellow board members and

the residents of the Flail Mower Nations.

I am conducting a poll of the flail mower owners

with flail mowers that use side slicer knives today:

The points to ponder and the answers to the questions

are either yes or no answers as I know you would rather

be out there using seat time to mow or do other chores.

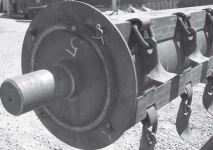

1.would you as a flail mower owner be interested in a

flail mower rotor that required no tools to change side

slicer knives?

2. If a wet well knife grinder was provided with the flail mower rotor

at no extra charge would that help in your decision to replace

your current flail mower rotor Yes or No?

3. would you be willing to ship the flail mower to have the flail mower

rotor exchanged with a complete set of new shorter side slicer knives

mounted on the flail mower rotor(plus 2 dozen spare knives) at no extra cost

if the price included round trip shipping to your door Yes or No?

4. would you ship your existing rotor to exchange it with a much improved four row flail mower rotor

that requires no tools to change knife sets and have the new knife sets mounted and

three dozen spare knives included in the price with prepaid shipping to your door?

5. how much would the improved mounting system and improved quality of cut affect your decision?

1. not at all:

"I wish to keep my current flail mower rotor"

2. somewhat:

"I have plenty to time to change side slicers if they are dull or broken"

3. completely:

"I have little time to change knives or flip them to the opposing sharp knife edge

in season and would use the flail mower more to mow"

I look forward to your responses to my polling.

the residents of the Flail Mower Nations.

I am conducting a poll of the flail mower owners

with flail mowers that use side slicer knives today:

The points to ponder and the answers to the questions

are either yes or no answers as I know you would rather

be out there using seat time to mow or do other chores.

1.would you as a flail mower owner be interested in a

flail mower rotor that required no tools to change side

slicer knives?

2. If a wet well knife grinder was provided with the flail mower rotor

at no extra charge would that help in your decision to replace

your current flail mower rotor Yes or No?

3. would you be willing to ship the flail mower to have the flail mower

rotor exchanged with a complete set of new shorter side slicer knives

mounted on the flail mower rotor(plus 2 dozen spare knives) at no extra cost

if the price included round trip shipping to your door Yes or No?

4. would you ship your existing rotor to exchange it with a much improved four row flail mower rotor

that requires no tools to change knife sets and have the new knife sets mounted and

three dozen spare knives included in the price with prepaid shipping to your door?

5. how much would the improved mounting system and improved quality of cut affect your decision?

1. not at all:

"I wish to keep my current flail mower rotor"

2. somewhat:

"I have plenty to time to change side slicers if they are dull or broken"

3. completely:

"I have little time to change knives or flip them to the opposing sharp knife edge

in season and would use the flail mower more to mow"

I look forward to your responses to my polling.