leonz

Super Member

Don't hate me, but I need pictures of the interior of the side weldments of the flail mower please

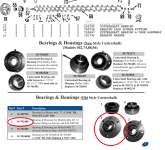

I would love to see more pictures of the bearings and housings facing the same direction also so I can be of more help.

My soap opera is on so I will be back in a while.

I would love to see more pictures of the bearings and housings facing the same direction also so I can be of more help.

My soap opera is on so I will be back in a while.