Pks

Platinum Member

- Joined

- Apr 6, 2000

- Messages

- 771

- Location

- Saline, Michigan

- Tractor

- Kubota L3700SU, Cub Cadet 1430, Hustler Super-Z 66in, Vermeer 1250

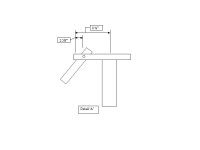

This is the tool I made when I installed a field fence in my yard. The fence is general purpose field fence from Tractor Supply. The fence is 330 ft long and 4 ft high. The spool was about 100 pounds.

I used the tool to hold the spool of fence while I pounded the T-posts into the ground. Two motorcycle tie-downs were used to hold the fence straight and very tight while I fastened the T-posts to the fence. The tie-downs looped around the ROPS support on the tractor's right side and then back to 2- 1x3s that sandwiched the wire fence.

I used the tool to hold the spool of fence while I pounded the T-posts into the ground. Two motorcycle tie-downs were used to hold the fence straight and very tight while I fastened the T-posts to the fence. The tie-downs looped around the ROPS support on the tractor's right side and then back to 2- 1x3s that sandwiched the wire fence.