Z RENCH

Silver Member

- Joined

- Jul 10, 2009

- Messages

- 151

- Location

- North Texas

- Tractor

- 09 Bobcat CT335,09 ct440,08 Kioti DK55, 10 DK45HST, 10 DK40HST, & an 09 John Deere 4720

and what position low middle or high does the toplink go on the back of the tractor?

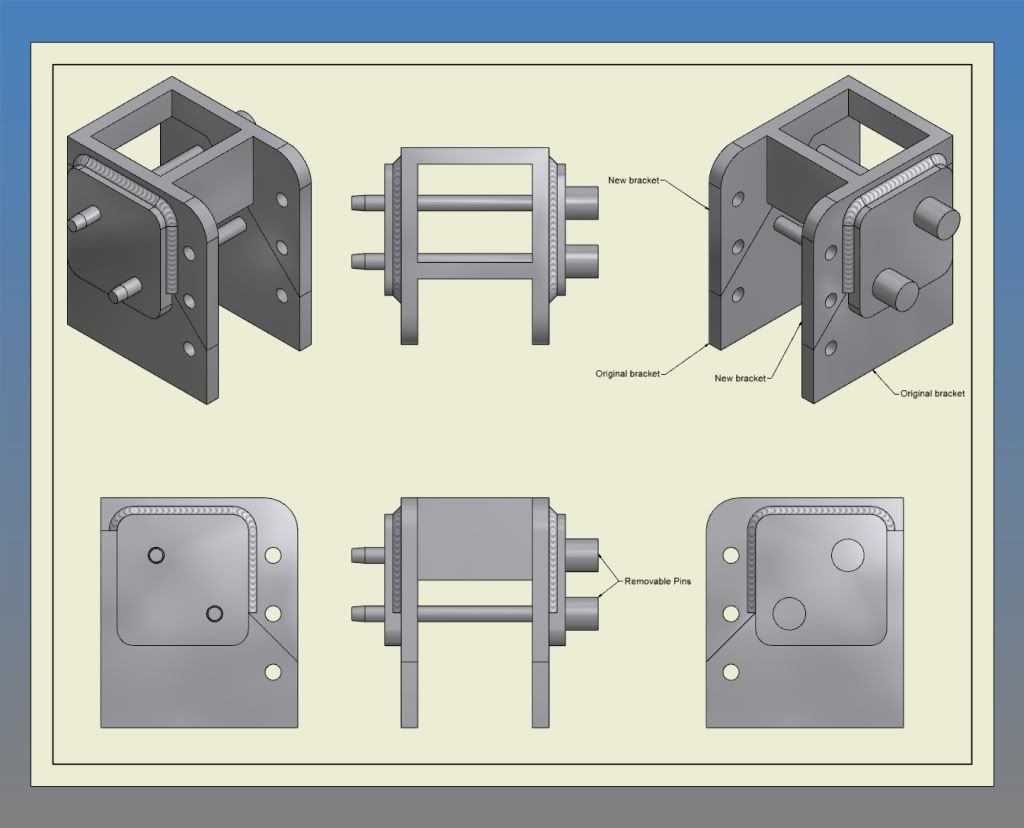

I bought a hydraulic top link (CCM brand) for my CT335 and am forced to put it in the bottom setting cause the housing is too wide to go into the center or top cause it would hit the tractor top link bracket when the 3 pt. position would be from half way to all the way down.