RedDirt

Gold Member

- Joined

- Dec 4, 2007

- Messages

- 469

- Location

- Northern Idaho

- Tractor

- Kubota BX23, Wards 16HP HST Garden Tractor, (previous) D2 Logging Cat

General consensus is that narrow BH buckets and compact dirt (clay) don't mix. The problem may be able to be solved with a self ejecting bucket.

Remarks on charlz "narrow bucket" thread (Built it Yourself), and my "build a slim trenching bucket?" thread (Kubota own/operate) indicate the likely possibility that when working in a high clay content soil the dirt sticks to a narrow trenching bucket and doesn't readily evacuate. This lead me on a search of "ejector buckets" and my thanks to pycoed (West Wales UK) for leading me to European designs.

US has little offerings for ejector buckets (that I could find). Some European backhoes seem to have a different bucket style and operation of the curl mechanism.

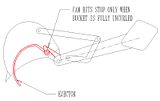

Here is a picture of a European ejector bucket (Harford) with a flap and levers:

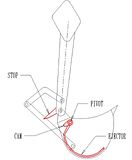

But this European design (Lackender ) caught my eye for simplicity:

The Lackender bucket must have a longer curl cylinder that goes over-center of the bucket pivot to fully curl the bucket. My challenge was to see how to make this "half-round, pivot-at-radius" bucket adapt to our shorter curl cylinders and bucket curl levers.

This is what my initial design looks like. (This is my first posting of pdf's. If they view sideways you should be able to click the "rotate" icon when it opens in Adobe to set it straight) When I reviewed my post this was the case AND they didn't open on the first try. On that (cant' open) screen I "canceled" then clicked the attachment once again and they opened fine. Can someone tell me how to better attach pdf's?

View attachment Ejector Bucket1 Layout1 .pdf

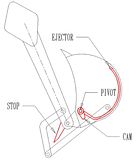

The concept is a 1/3 circle bucket that pivots at the center of the radius. There is a fixed flat plate that is "U" bolted to the bottom of the dipper stick. When the bucket is fully opened the bucket rotates around the fixed plate and ejects the bucket contents.

A modified digging style will be necessary with this bucket. As you begin the trench all the digging must be done with the curl because the fixed plate blocks the opening. This motion must be done a couple of scoops full then I think digging can be resumed in a more familiar manner abet modified somewhat.

This drawing shows the first few scoops being removed on the way to a 3ft deep trench.

View attachment Ejector Bucket1 Layout2 .pdf

An interesting point is the volume of this 7" wide bucket when fully curled (and dirt filled to the ejector plate) is the same as my 12" bucket. This is due to the larger (12"+/-) radius of the ejector bucket (my standard 12" bucket has about a 5" radius back, about 1/3 of a circle. then radiates straight-lined about 5 1/2" beyond the spring points of the curved back).

This is an initial design phase and I'd sure value any feedback and comets before I start a mock-up. I realize the fixed plate attachment needs to be worked out better; it is shown and explained as "U" bolted for concept purpose. The plate is likely to be 1/4" thick with a couple of "L" angles welded on the face for stiffeners.

Remarks on charlz "narrow bucket" thread (Built it Yourself), and my "build a slim trenching bucket?" thread (Kubota own/operate) indicate the likely possibility that when working in a high clay content soil the dirt sticks to a narrow trenching bucket and doesn't readily evacuate. This lead me on a search of "ejector buckets" and my thanks to pycoed (West Wales UK) for leading me to European designs.

US has little offerings for ejector buckets (that I could find). Some European backhoes seem to have a different bucket style and operation of the curl mechanism.

Here is a picture of a European ejector bucket (Harford) with a flap and levers:

But this European design (Lackender ) caught my eye for simplicity:

The Lackender bucket must have a longer curl cylinder that goes over-center of the bucket pivot to fully curl the bucket. My challenge was to see how to make this "half-round, pivot-at-radius" bucket adapt to our shorter curl cylinders and bucket curl levers.

This is what my initial design looks like. (This is my first posting of pdf's. If they view sideways you should be able to click the "rotate" icon when it opens in Adobe to set it straight) When I reviewed my post this was the case AND they didn't open on the first try. On that (cant' open) screen I "canceled" then clicked the attachment once again and they opened fine. Can someone tell me how to better attach pdf's?

View attachment Ejector Bucket1 Layout1 .pdf

The concept is a 1/3 circle bucket that pivots at the center of the radius. There is a fixed flat plate that is "U" bolted to the bottom of the dipper stick. When the bucket is fully opened the bucket rotates around the fixed plate and ejects the bucket contents.

A modified digging style will be necessary with this bucket. As you begin the trench all the digging must be done with the curl because the fixed plate blocks the opening. This motion must be done a couple of scoops full then I think digging can be resumed in a more familiar manner abet modified somewhat.

This drawing shows the first few scoops being removed on the way to a 3ft deep trench.

View attachment Ejector Bucket1 Layout2 .pdf

An interesting point is the volume of this 7" wide bucket when fully curled (and dirt filled to the ejector plate) is the same as my 12" bucket. This is due to the larger (12"+/-) radius of the ejector bucket (my standard 12" bucket has about a 5" radius back, about 1/3 of a circle. then radiates straight-lined about 5 1/2" beyond the spring points of the curved back).

This is an initial design phase and I'd sure value any feedback and comets before I start a mock-up. I realize the fixed plate attachment needs to be worked out better; it is shown and explained as "U" bolted for concept purpose. The plate is likely to be 1/4" thick with a couple of "L" angles welded on the face for stiffeners.