MJPetersen

Veteran Member

This past fall I decided that my hobby needed to generate some income to pay for itself. With winter coming I thought that I should be able to do that by making a RB to plow snow for businesses and people here. That was my plan. But you know that while I read of all the snow in the States and the difficulties with the severe winter weather--we did not get any snow to speak of. So much for my income hopes! But this spring I decided to finish my project and to post my most modest efforts for your amusement,

So much for my income hopes! But this spring I decided to finish my project and to post my most modest efforts for your amusement, or encouragement.

or encouragement.

Those who remember my past threads know that implements for small tractors here are hard to find and generally expensive. So that is what prompted the build.

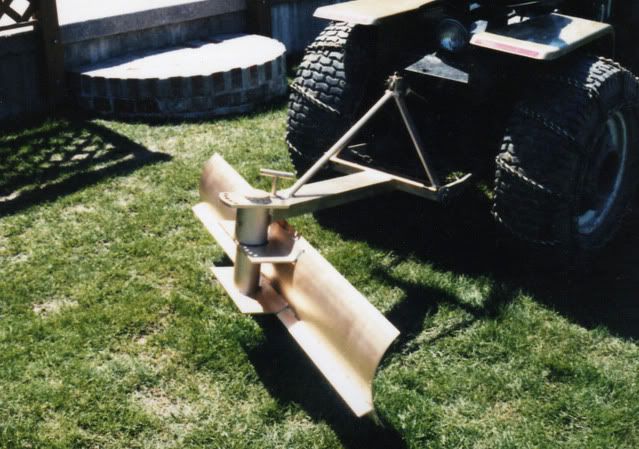

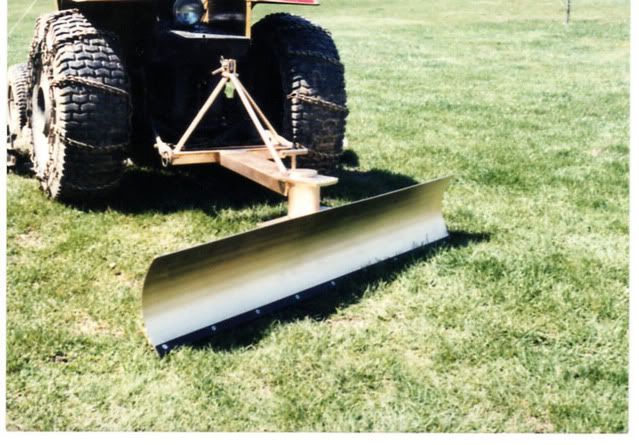

In order to make it truly economical I checked and found that I had most of what I would need in my scrap collection. I did need to get the main blade piece. I had it rolled to get the curve and I cut off the straight edges from the rolling in order to made the offset for the cutting edge.

I also welded a straight back for the blade and triangular braces down on the cutting edge as my plan is to use this for more than a blade for snow.

I want to use this with a metal cutting edge for dirt and a rubber edge for snow so I made a template which will double as the retainer for the rubber edge. I also want to have gauge wheels on it for super smooth finishes, so that had to be taken into account at the beginning.

These first pics are of the 3pt frame and the blade. More pics will be forthcoming as I finish things.

Mike

Those who remember my past threads know that implements for small tractors here are hard to find and generally expensive. So that is what prompted the build.

In order to make it truly economical I checked and found that I had most of what I would need in my scrap collection. I did need to get the main blade piece. I had it rolled to get the curve and I cut off the straight edges from the rolling in order to made the offset for the cutting edge.

I also welded a straight back for the blade and triangular braces down on the cutting edge as my plan is to use this for more than a blade for snow.

I want to use this with a metal cutting edge for dirt and a rubber edge for snow so I made a template which will double as the retainer for the rubber edge. I also want to have gauge wheels on it for super smooth finishes, so that had to be taken into account at the beginning.

These first pics are of the 3pt frame and the blade. More pics will be forthcoming as I finish things.

Mike