Iplayfarmer

Super Member

Well, I'm sure some of you saw this one coming. I am too much of a cheapskate to fork out twice what I paid for the tractor to put a loader on it. I've got a big head now from my experience building a hydraulic dump trailer, and now I'm going to build a front end loader for my Massey Ferguson 1215. If all goes well, I'll build a backhoe for it too.

Everyone was so helpful throughout the dump trailer build, and I just had to start this project out by posting here on TBN. I owe MossRoad big for his excellent example of how to post a project. Anyone who hasn't read his backhoe build should dedicate and afternoon to it. It's really pretty good.

I'm just in the planning stage and the accumulating junk stage. I've promised my wife that I will do a few projects around the house before I start work on the loader, but in the mean time I can plan, dream, and keep my eyes out for deals on materials.

There's a tractor and farm machinery wrecking yard about 20 miles away, and the guy that runs the place owes a few favors to a close friend of mine. I took said friend with me on Monday and picked up all the hydraulics that I'd need for both a backhoe and a front end loader.

I got the 5 spool valve and the 3 spool valve in the attached picture plus the 10 rams of various lengths and diameters all for $350. All are guaranteed to work.

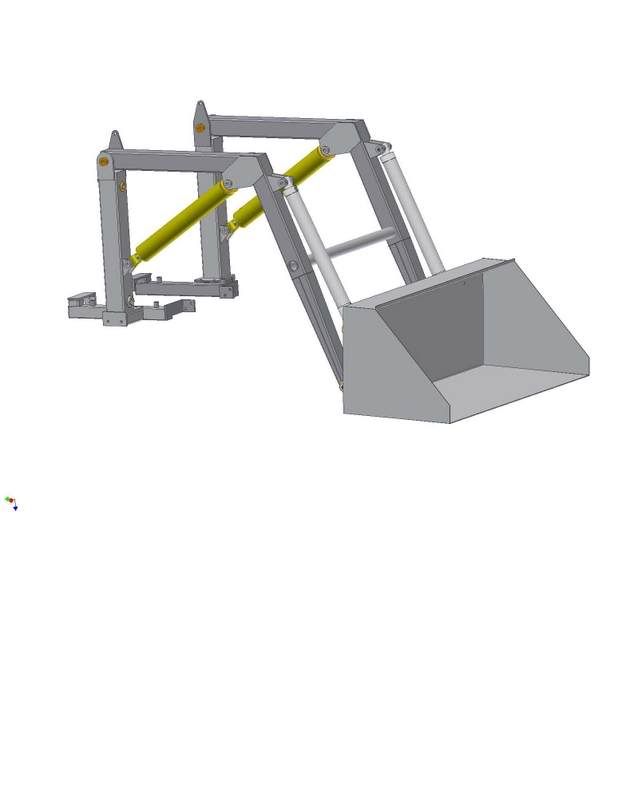

I've been using google sketchup to do some initial modeling and figuring. (Thanks hazmat for recommending it to me clear back in September.) The second picture is a shot from sketchup of the loader as it is designed so far. I still plan on considering a load leveling system, and I've got the third spool on the valve to keep my options open for a grapple or something like it.

I'm just introducing the project right now. Be patient with me and I will post back with plenty of pictures, stories, lessons learned, and I'm sure lots of questions.

Everyone was so helpful throughout the dump trailer build, and I just had to start this project out by posting here on TBN. I owe MossRoad big for his excellent example of how to post a project. Anyone who hasn't read his backhoe build should dedicate and afternoon to it. It's really pretty good.

I'm just in the planning stage and the accumulating junk stage. I've promised my wife that I will do a few projects around the house before I start work on the loader, but in the mean time I can plan, dream, and keep my eyes out for deals on materials.

There's a tractor and farm machinery wrecking yard about 20 miles away, and the guy that runs the place owes a few favors to a close friend of mine. I took said friend with me on Monday and picked up all the hydraulics that I'd need for both a backhoe and a front end loader.

I got the 5 spool valve and the 3 spool valve in the attached picture plus the 10 rams of various lengths and diameters all for $350. All are guaranteed to work.

I've been using google sketchup to do some initial modeling and figuring. (Thanks hazmat for recommending it to me clear back in September.) The second picture is a shot from sketchup of the loader as it is designed so far. I still plan on considering a load leveling system, and I've got the third spool on the valve to keep my options open for a grapple or something like it.

I'm just introducing the project right now. Be patient with me and I will post back with plenty of pictures, stories, lessons learned, and I'm sure lots of questions.