dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,660

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

This thread will describe what I went through in the design and build process

for a hydraulicly operated thumb for my Prairie Dog backhoe attachment.

Those who have seen my previous DIY thumb postings will note the many

similarities to my Fixed Mechanical Backhoe Thumb (1st and 2nd generations),

and my Articulated Mechanical Backhoe Thumb. Here is the link:

http://www.tractorbynet.com/forums/build-yourself/94333-another-backhoe-mechanical-thumb-fixed.html (Photo 1 is the fixed Gen 2 thumb.)

I did use a modified version of my Generation 2 thumb, but going hydraulic

meant substantial and laborious changes. Over the last several months, I

have been experimenting with cylinders and valves to achieve my design

goals. This hydraulic thumb is all new, and not a conversion of one of my

mechanical thumbs. I have recently completed the project and it works

great. Over the next few days, I will post 18 pix and share the process I

went through.

Two of my design goals were to be able to completely retract the thumb

when not in use, and to be able to grasp objects with more "dexterity" than

a fixed thumb. Both activities had to be performed from the operator's seat.

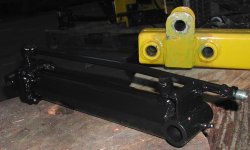

First, the experiments. As a mock-up, I took a 2x8 cylinder I had and

substituted it for the toplink I use for the mechanical thumb brace (2nd

photo). I connected this cylinder in parallel with the curl cylinder so

they operated simultaneously when the curl circuit is activated. This

functionality was very effective in grasping rocks and logs since equal hyd

pressure goes to both cyls. (3rd photo) I moved a lot of rocks and

logs with this setup.

My force calculations and thumb geometry showed that my 2" cylinder

would apply slightly greater force than the bucket at its maximum force

position. At full thumb extension, the bkt force became slightly larger as

the 2 moment arm lengths changed. A 2" cylinder would be best. The

stroke would need to be 11 inches to achieve the desired travel.

for a hydraulicly operated thumb for my Prairie Dog backhoe attachment.

Those who have seen my previous DIY thumb postings will note the many

similarities to my Fixed Mechanical Backhoe Thumb (1st and 2nd generations),

and my Articulated Mechanical Backhoe Thumb. Here is the link:

http://www.tractorbynet.com/forums/build-yourself/94333-another-backhoe-mechanical-thumb-fixed.html (Photo 1 is the fixed Gen 2 thumb.)

I did use a modified version of my Generation 2 thumb, but going hydraulic

meant substantial and laborious changes. Over the last several months, I

have been experimenting with cylinders and valves to achieve my design

goals. This hydraulic thumb is all new, and not a conversion of one of my

mechanical thumbs. I have recently completed the project and it works

great. Over the next few days, I will post 18 pix and share the process I

went through.

Two of my design goals were to be able to completely retract the thumb

when not in use, and to be able to grasp objects with more "dexterity" than

a fixed thumb. Both activities had to be performed from the operator's seat.

First, the experiments. As a mock-up, I took a 2x8 cylinder I had and

substituted it for the toplink I use for the mechanical thumb brace (2nd

photo). I connected this cylinder in parallel with the curl cylinder so

they operated simultaneously when the curl circuit is activated. This

functionality was very effective in grasping rocks and logs since equal hyd

pressure goes to both cyls. (3rd photo) I moved a lot of rocks and

logs with this setup.

My force calculations and thumb geometry showed that my 2" cylinder

would apply slightly greater force than the bucket at its maximum force

position. At full thumb extension, the bkt force became slightly larger as

the 2 moment arm lengths changed. A 2" cylinder would be best. The

stroke would need to be 11 inches to achieve the desired travel.