Hi Guys,

I was sitting eating my lunch thinking about this and trying to apply the KISS principle. The barb end bolts are difficult to source so I had a bit of a rethinkThe main criteria are that:

1. its cheap

2. the parts are readily available anywhere

3. the amount of handling is minimised. even slipping a pointed guide over a bolt will become tiresome after 1000 joints

4. Ideally it would be nice to be able to do it all from the seat of the skidsteer

5. The mats are moved twice a year, once to place on pit and once to remove.

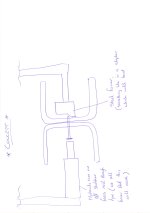

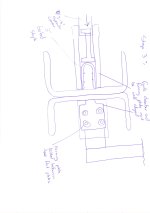

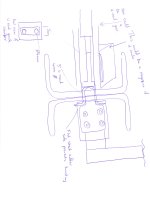

One simple idea I came up with was to use galvanised steel nails. We all know that these will go through a tyre. If I could get one with a wider than average head so that it will act like a washer. On the other side of the implement there would be a steel block that would act like the plate on the bottom of a stapler. It would cause the nail to bend 90 degrees + thus preventing it from pulling back out?

Do you think this would work? Here are some simple sketches, 1000 words and all that. Id appreciate your thoughts....

Ron

I was sitting eating my lunch thinking about this and trying to apply the KISS principle. The barb end bolts are difficult to source so I had a bit of a rethinkThe main criteria are that:

1. its cheap

2. the parts are readily available anywhere

3. the amount of handling is minimised. even slipping a pointed guide over a bolt will become tiresome after 1000 joints

4. Ideally it would be nice to be able to do it all from the seat of the skidsteer

5. The mats are moved twice a year, once to place on pit and once to remove.

One simple idea I came up with was to use galvanised steel nails. We all know that these will go through a tyre. If I could get one with a wider than average head so that it will act like a washer. On the other side of the implement there would be a steel block that would act like the plate on the bottom of a stapler. It would cause the nail to bend 90 degrees + thus preventing it from pulling back out?

Do you think this would work? Here are some simple sketches, 1000 words and all that. Id appreciate your thoughts....

Ron