dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,174

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

I have wanted to build one of these for a long time, and at last I

have completed it. I have already used it to trim some of my many trees,

and to lift and attach the last pieces of metal roofing to my new

wood shed. I have created a video of the new manlift in operation.....the

link is at the end of this thread.

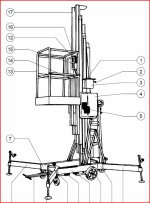

I started with a Genie AWP24 manlift, which I purchased used (and non-

operational) from my local rental yard. These units are designed to be

pushed around manually, then they telescope vertically with up to 300

pounds in the basket. Outriggers are attached and leveled first. The

third picture is from the operator's manual.

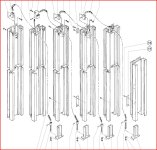

These units are pretty unwieldy, weighing in at about 650 lb. There are

also 19, 30, and 36-foot versions that use more or less sections in the

telescoping boom.

My goal is to adapt this to the loader on my Kioti CK30 tractor.

have completed it. I have already used it to trim some of my many trees,

and to lift and attach the last pieces of metal roofing to my new

wood shed. I have created a video of the new manlift in operation.....the

link is at the end of this thread.

I started with a Genie AWP24 manlift, which I purchased used (and non-

operational) from my local rental yard. These units are designed to be

pushed around manually, then they telescope vertically with up to 300

pounds in the basket. Outriggers are attached and leveled first. The

third picture is from the operator's manual.

These units are pretty unwieldy, weighing in at about 650 lb. There are

also 19, 30, and 36-foot versions that use more or less sections in the

telescoping boom.

My goal is to adapt this to the loader on my Kioti CK30 tractor.