piller

Gold Member

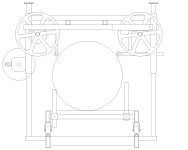

What is the layout configuration that you are thinking about for the tractor PTO and horizontal cutting bandsaw?

By this I mean would the log be parallel to the rear axle of the tractor or would the log be perpendicular to the tractor rear axle?

When you say stationary, do you mean that the sawmill will only be operated in one location or that the sawmill will be portable and operated in different locations but that once it is setup the bandsaw will be stationary?

By this I mean would the log be parallel to the rear axle of the tractor or would the log be perpendicular to the tractor rear axle?

When you say stationary, do you mean that the sawmill will only be operated in one location or that the sawmill will be portable and operated in different locations but that once it is setup the bandsaw will be stationary?