Hi All,

I am developing plans to build a Brush Cutter to go on the front of my NH 190 skid steer and my NH TN70D tractor. The tractor has a quick attach plate on the FEL and Hyd remotes on the loader.

I have seen several videos of these thing working and I rented a Rhino SM60 to use with the skid steer. I'm very impressed with what they can do. The purpose of developing these plans is to see if I can beat the price of a commercially built brush cutter. I have welders and a fairly well equipped machine shop at home and of course the plans will be tailored towards something I have the equipment and skills to build.

I have posted some questions in the hydraulics forum regarding the hydraulic motor and other drive components. Is it possible to cross link these posts between forums?

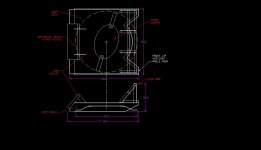

Here is the drawing for the brush cutter so far. Much more development to be done.

I would appreciate a reality check for what I am planning. Any suggestions and advise will be most welcome.

Thanks,

Tim

I am developing plans to build a Brush Cutter to go on the front of my NH 190 skid steer and my NH TN70D tractor. The tractor has a quick attach plate on the FEL and Hyd remotes on the loader.

I have seen several videos of these thing working and I rented a Rhino SM60 to use with the skid steer. I'm very impressed with what they can do. The purpose of developing these plans is to see if I can beat the price of a commercially built brush cutter. I have welders and a fairly well equipped machine shop at home and of course the plans will be tailored towards something I have the equipment and skills to build.

I have posted some questions in the hydraulics forum regarding the hydraulic motor and other drive components. Is it possible to cross link these posts between forums?

Here is the drawing for the brush cutter so far. Much more development to be done.

I would appreciate a reality check for what I am planning. Any suggestions and advise will be most welcome.

Thanks,

Tim