Re: help with scissor lift on a dump truck

may be I am figuring things wrong here,

but in the second post the first picture in the line of three about mid way, is you max lifting you have the most leverage at where the hoist is in that picture,

http://www.tractorbynet.com/forums/...07-help-scissor-lift-dumpp-truck-p1060057.jpg

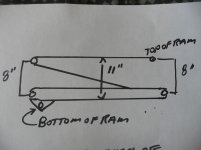

you have what looks like a full 8 inches from the pivot point, and the arm on the top of the loader (first post) last picture

http://www.tractorbynet.com/forums/...69-help-scissor-lift-dumpp-truck-p1060036.jpg

looks to be about 27.5 inches,

at that point you have about 3.5 to 1 disadvantage, so if you have a 4" cylinder, 12.56 square inches of piston, and at 2000 psi you have 25120 pounds of push, so if you divide it by 3.5 you have about 7177 pounds of push at the end of the hoist,

the problem is when your totally collapsed you most likely only have about 3" above the pivot point, so your leverage is reduced, if it is only 3 inches above the pivot point you leverage is about 9 to 1 so your initial lift is only 2791 pounds of beginning lift, then as the cylinder end works through the arc, it is increases at the point in the picture, and then decrease again on the opposite side,

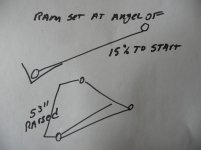

If you look at the second page of the Dewey hoist, the max distance form the pivot link is at the beginning, and then as it unfolds the distance is reduced but also allows the cylinder to fully extend,

IMO you need more power, or initial leverage or distance from the pivot point, so you start the lift of the bed,

by raising the point where the cylinder rod attach駸 will help, but it may not fully extend or not lift as high, by reducing the length of the lift arm you would increase the lifting power as well, by re attaching the lift arms pivot point closer to the hing you would nearly maintain the lift, but you also lose a little by having more front weight on the bed, the other answer is more cylinder, (larger), or pressure.

like I said that is my two cents,

~~~~~~~~~~~~~~~~~~~~~~~~~~~

Added in edit,

now if you do it with out the double hinge or not, you want the greatest leverage at the beginning, but look at the hing on the Dewey hoist, I put a picture of it in, you can see the beginning of it is the greatest distance, (leverage) at the beginning of the lift, and then as it arcs through the swing it lessens and in the process extends faster, one could add a little mount up on top of the current assembly you have and make the distance longer it may or may not work, by moving the cylinder back and up may work, with out major rebuild, you could just wait for your new power pack and at 2700 it may do it all, with out any changes, to the hoist, your current unit may only be a 1500 unit or less,

most hydraulics work at a disadvantage but do to the power they have it usually is able to over come that disadvantage, many of the old side dumps had small cylinders but they were telescoping units, but there push was nearly straight with out any loss of mechanical advantage,

I think I said all I can say at this point,

Hello all sorry if I have posted somthing that has already ben coverd

Hello all sorry if I have posted somthing that has already ben coverd