stuartmcraycattle

New member

- Joined

- Jan 29, 2012

- Messages

- 15

- Tractor

- Case JX75

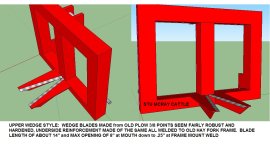

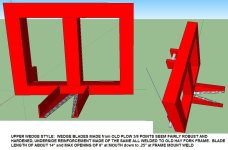

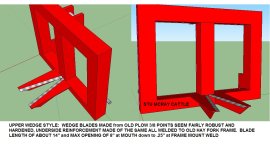

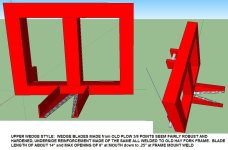

Well I have found another spare old hayfork frame that should be more than robust to go at another tree removing idea ( god I hate cedar trees and honey locusts ).... So I have two designs to get the TBN gurus opinion on which would be the strongest ( aka least likely to fail ) version of my design... the wedge puller will be mounted on the rear 3pt of a Case JX75 4wd, I plan on having an hydraulic upper link to give the blade wedge an adjustable angle of attack when backing into the tree of choice I am guessing 10 to 15 degrees of an upward angle to help the wedge factor bite into the base of the tree??? My initial thoughts are that the upper blade setup with under support beams would be stronger for upward force pulling but I am not quite sure if my logic is correct.. Thanks for all and any opinions on this as I want to cut, fab and weld one time on this project...sorry the second pic is the lower blade design I labeled it wrong in the design program dang it....