jwmorris

Veteran Member

- Joined

- Oct 3, 2007

- Messages

- 1,039

7 years ago or so, I decided To cast my own bullets but after watching a friend cast fishing weights, I thought the process was too time consuming for the volume I was looking for. So I did some research and wound up building the machine below.

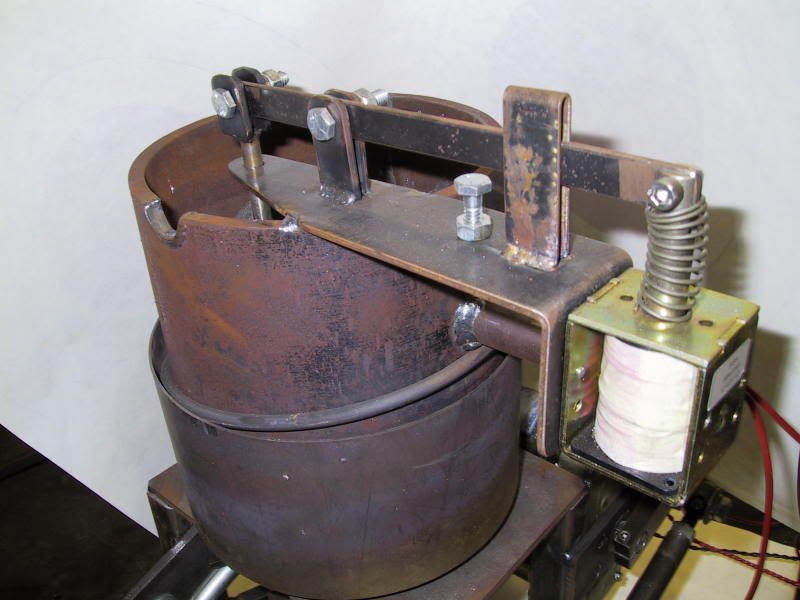

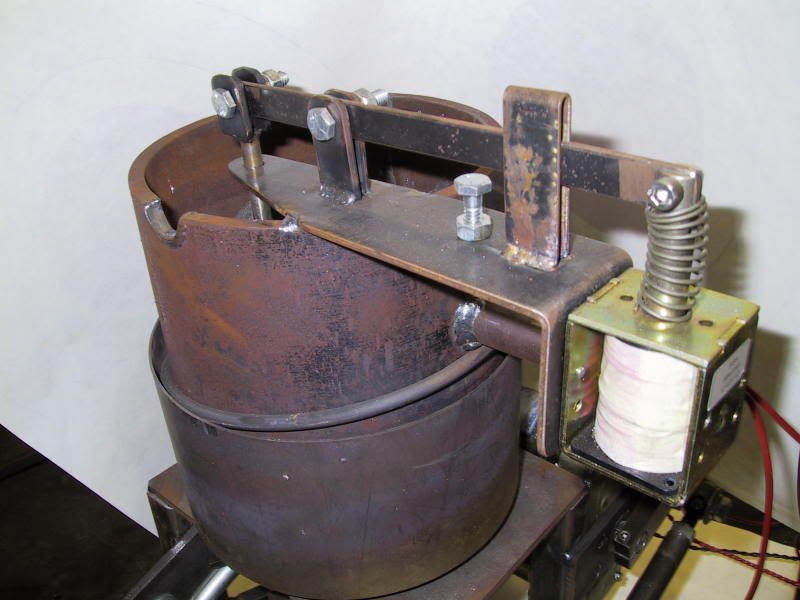

The pot is 3/8" wall pipe that I welded on a bottom that has a needle and seat style valve I made. The solenoid on top is connected to the stainless needle valve and a timer I built controls the open time precisely with a ten turn potentiometer on the control panel. The 1/4-20 bolt is adjustable for flow. It holds a little over 60#s of lead.

Most electric heating elements are expensive so I went to Sears and bought a replacement 3500 oven element for $12 and bent it around the pipe. The PID controller and a solid state relay round out the heating part of the machine.

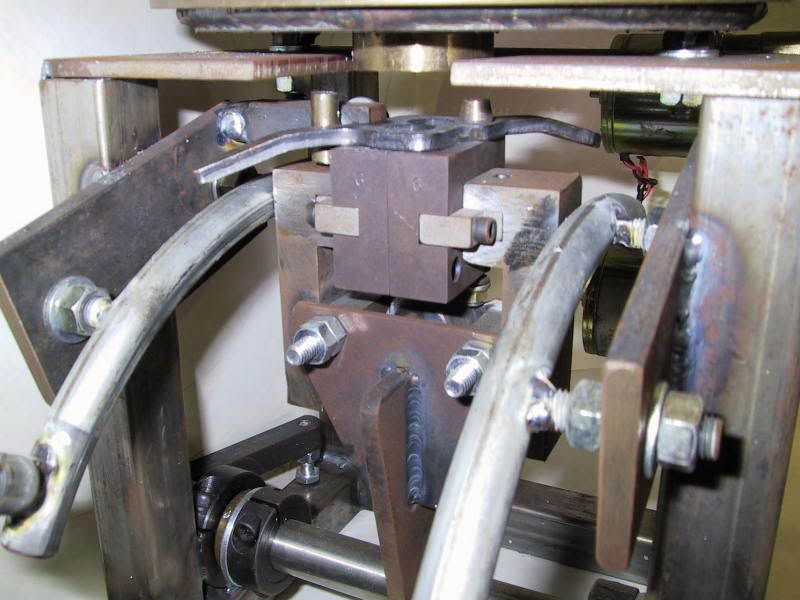

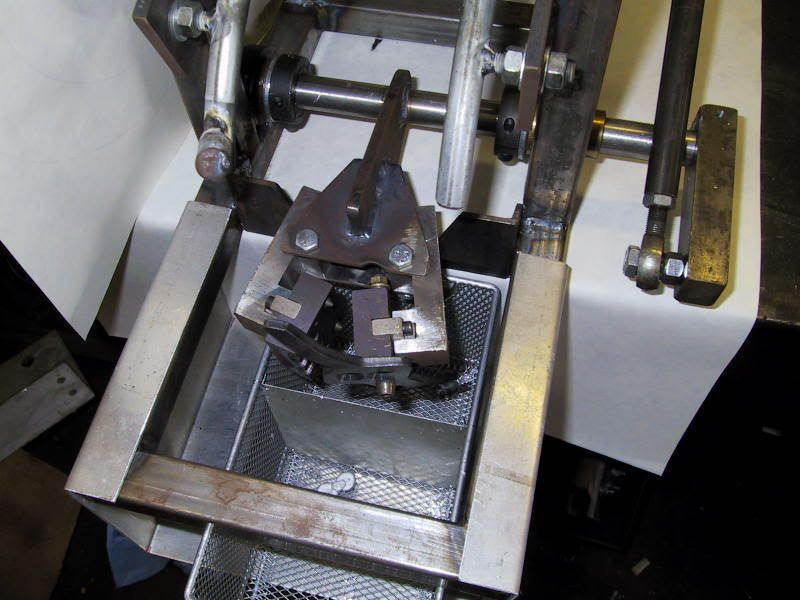

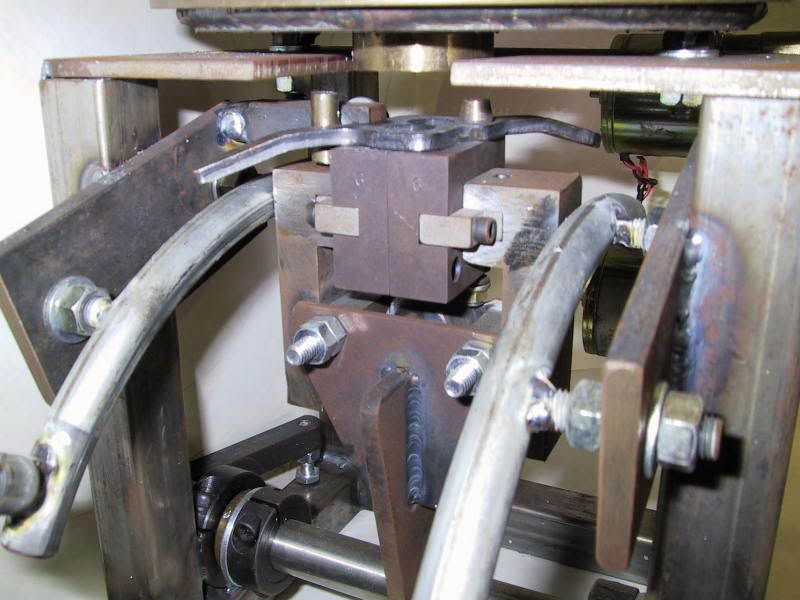

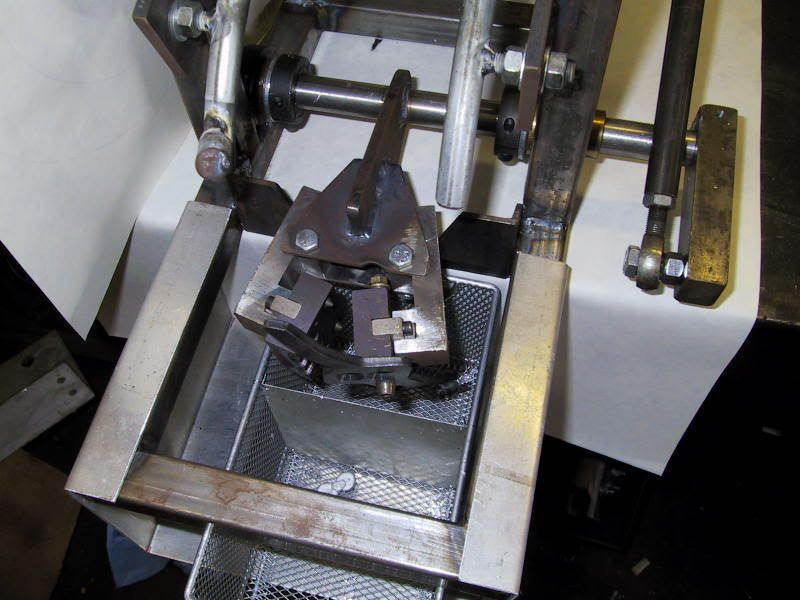

The mold carrier arms are machined to use standard hand style molds held in with two roll pins. The guide rods are adjustable to clamp the mold tight at the end of the "up" stroke and two sections of angle iron at the bottom of the stroke open up the molds. The little tip on the left side 1/2" rolled steel guide rod, is to open and close the sprue cutter. There is a divider in the basket so bullets and sprues are separated so I don't have to pick through them to remelt.

It's not the most beautiful contraption but it sure saves a lot of money and time.

The pot is 3/8" wall pipe that I welded on a bottom that has a needle and seat style valve I made. The solenoid on top is connected to the stainless needle valve and a timer I built controls the open time precisely with a ten turn potentiometer on the control panel. The 1/4-20 bolt is adjustable for flow. It holds a little over 60#s of lead.

Most electric heating elements are expensive so I went to Sears and bought a replacement 3500 oven element for $12 and bent it around the pipe. The PID controller and a solid state relay round out the heating part of the machine.

The mold carrier arms are machined to use standard hand style molds held in with two roll pins. The guide rods are adjustable to clamp the mold tight at the end of the "up" stroke and two sections of angle iron at the bottom of the stroke open up the molds. The little tip on the left side 1/2" rolled steel guide rod, is to open and close the sprue cutter. There is a divider in the basket so bullets and sprues are separated so I don't have to pick through them to remelt.

It's not the most beautiful contraption but it sure saves a lot of money and time.