CDN Farm Boy

Veteran Member

The one thing you're not taking into account is most wood will pop long before being split the full 16". I've had charlie horses and had to turn to protect the jewels (hence the charlie horses) from rounds exploding from off my splitter. So, you'll get a lot of deflection in the first couple inches of the cut, but soon the wood will open up, even if it doesn't fully split. That will lessen the amount of spread by the time you've split the round. Some wood, like hard maple, will do this much more than something like elm, but even elm will open up a little. A lot of the wood I split, I only have to move the splitter cylinder 6" - 8" to fully split rounds.

That makes sense. I have zero experience on a splitter while paying attention to HOW the wood moves rather than just keeping hands out of the way and deciding if a re-split is required.

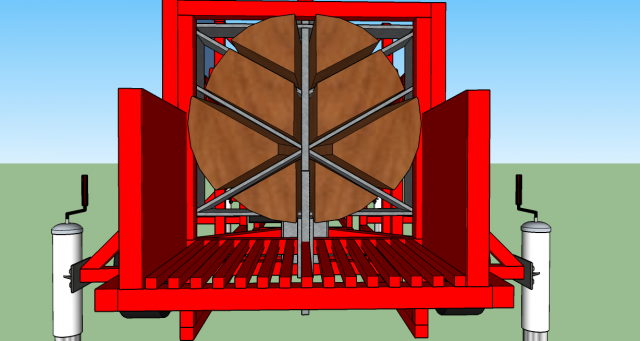

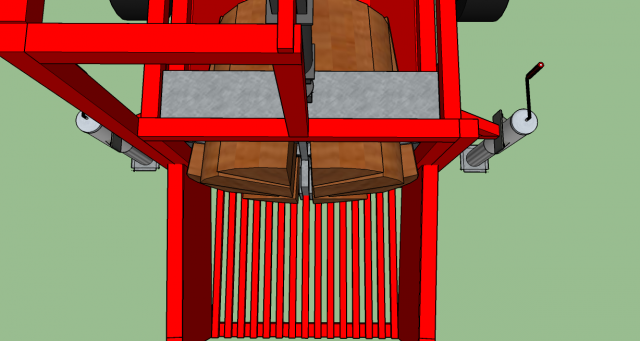

I think if you dropped the wood tray down 3" behind the processor, you'd eliminate the lift on the 4 way.

I agree.