deanwerden

Silver Member

My dad built a log splitter probably 20 years ago that was battery operated and used a tail gate loader, 10 years ago we upgraded to a China motor and pump that seems to be working pretty good. At the time we were just splitting about 2 cord a wood to heat the garage. 4 years ago I bought a place and am burning wood full time so I am using the splitter quite a bit and wanted to make some improvements. I am using the same cylinder power pack and spindle/wheels But everything else is new for the most part

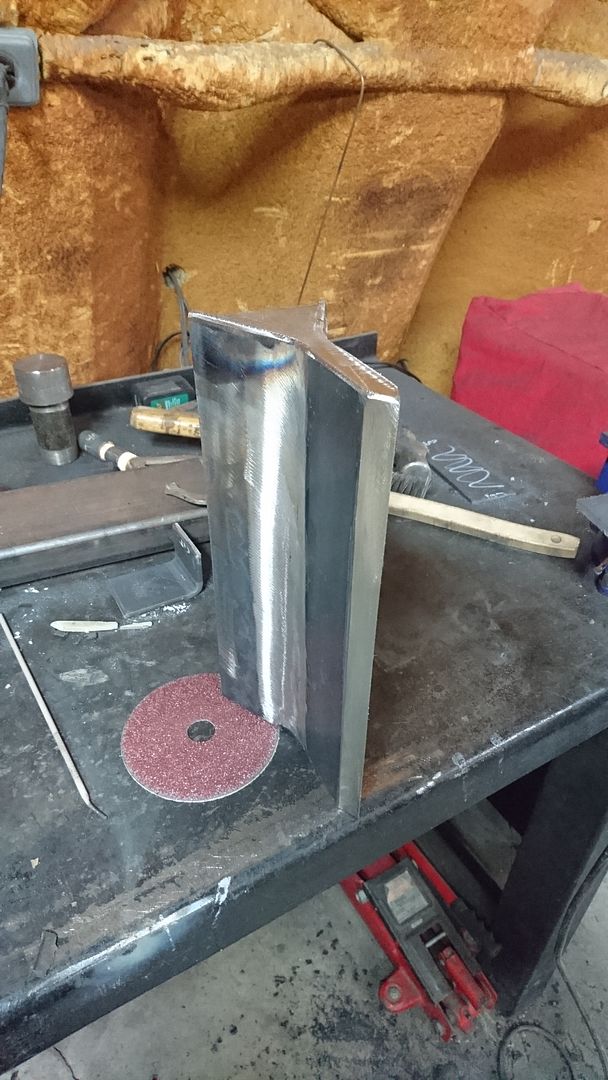

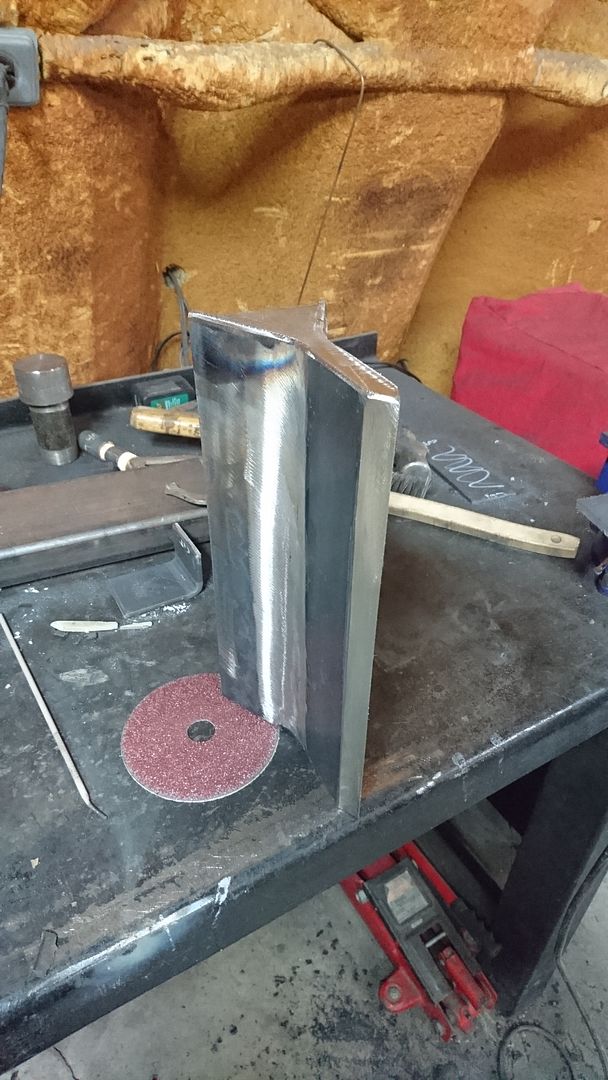

Here's my new wedge, the old splitter had the wedge on the ram and I'm going to a fixed wedge and pusher plate

One if the major draw backs of the other splitter is that it only has about a 1.5 gallon tank and the oil heats up quick and performance suffers. I am doing a tank axle like most splitters these days have, this holds about 9 gallons and I plan to add sections of the same tube on an angle towards the knife to increase capacity and strength

4 way adjustable wedge

That's all I have for now, Tommorow I will weld the ends on the tank and add a fitting for suction strainer, return, drain and vent

Here's my new wedge, the old splitter had the wedge on the ram and I'm going to a fixed wedge and pusher plate

One if the major draw backs of the other splitter is that it only has about a 1.5 gallon tank and the oil heats up quick and performance suffers. I am doing a tank axle like most splitters these days have, this holds about 9 gallons and I plan to add sections of the same tube on an angle towards the knife to increase capacity and strength

4 way adjustable wedge

That's all I have for now, Tommorow I will weld the ends on the tank and add a fitting for suction strainer, return, drain and vent