Confirmed with MVD, I'll be able to register it, and I will not need to have a VIN inspection done by the police, it can be handled right at MVD. There are three forms to fill out, and reciepts and a weight slip are both needed. They will assign a VIN, affix it while checking to make sure there isn't one already, and I'll be able to register and title it on the spot.

Now where was I?? Oh, yes... Stake pockets and rub rail...

I bought stake pockets from Ebay, and after putting it all together, it seemed rather empty between the pockets... I recalled seeing something there on one of the trailers I looked at... Turns out they're called "chain spools". Just a short piece of 1.5" pipe, welded between the stake pockets.

I got some of them done in this picture, near the fender, and some still to do closer to the camera...

I put my lovely wife to work sawing the pipe chunks while I welded them in... She likes my HF porta-band too.

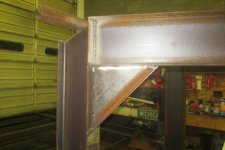

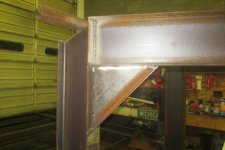

While the trailer was right-side up, I also welded in some 2" angle to function as ramp holders under the deck.

Hmm... Somewhere along here I cut up a piece of 10" light channel to make the rear of the trailer, including tail lights and ramp slots, and welded it on too, along with doors to cover the ramp slots...

Here's a pic of the trailer back upside-down (the last flip...) so I could weld rub rail/pockets/spools and ramp and bumper stuffs from the bottom.

At that point, the deck was pretty much done. Time to start putting the tongue together... (Sorry for the picture quality going to crap... My camera is dying at this point...)

Laid out the horizontal parts on the floor and beveled and tacked them. When the both matched, I final welded them. Just a bit of pre-heat got much improved penetration... My Hobart 190 welder is borderline for 1/4" steel without a bit of heat first... Once the first bead has been run, there's plenty of heat to get good penetration.

Took those two pieces and welded them to the hitch tube.

Couple of flips to get all the weldable areas and it's solid.

At this point, I wasn't comfortable doing the welding on the two remaining tongue joints... But there's a guy in the complex here that is a certified welder, and he came down with his truck and arc welded the rest of the tongue together for me. Sorry for the crappy camera pics, but his welds are solid. I added gussets to both sides after he was done with the main welds.

At this point, I was starting to see the light at the end of the tunnel. I cut a few braces for the tongue, some of which are also a place to mount the spare tire and welded them in...

Oh, so before welding on the tongue, I slipped an axle under it so I could move it around... And discovered that the spring hangers were not where they were supposed to be.

I had been messing with the model to figure out where the best spacing was to get the most suspension movement before binding. I finally decided on 29.25" as being ideal for my spring length... But somehow when I welded them on, I put them at 26, which was the actual spring length. Oops... So I got to grind off the welds on the front and rear hangers and re-weld them.

I'm getting fairly good at welding upside-down... Not that I wanted that skill...

I also drilled some holes to mount the electrical and breakaway boxes, and 3/4" holes for the LED marker lights... And added some angle to the vertical I beams to weld the jacks to eventually...

And then I primed it with rustoleum, rusty metal primer for the rusty places, and clean metal primer for the rest...