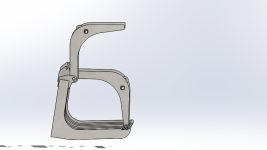

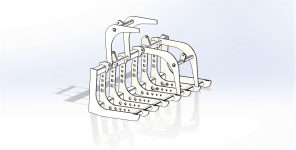

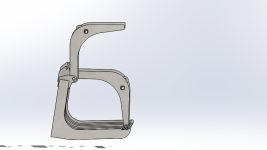

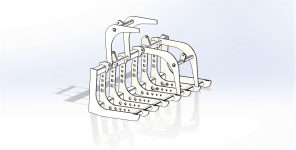

Hi guys and girls. New here and am amazed at the information thats on here. been looking around and figured this is the perfect place to ask for some pointers. Been playing with solidworks for a few months now and after looking around for ideas on building a grapple i came up the this idea ..so far. Going to make it out of 1/2 plate as im making it for a 90 hp loader..but my biggest question is what angle do i make the back where the quick attach goes to and what effect does having the angle too much or not enough have.. Any ideas what i should change or add is welcomed and appreciated.

Last edited: