polemidis

Gold Member

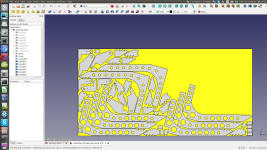

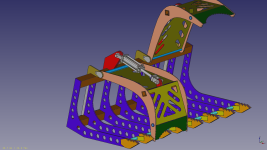

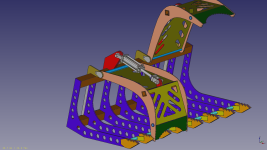

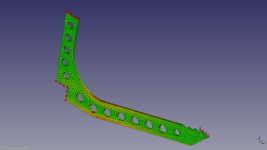

I finished this grapple.

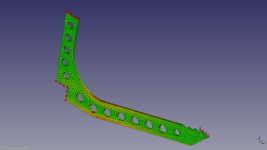

And did some FEM analysis, and revealed that I need to tweak it a little bit.

The only place that I am stuck and cannot analyse due to my software's limitation is the lid. Can anyone help me with his experience? What should be the thickness/size of a) the square tubing on the lid where the cylinder rod pushes? b) the thickness of the flat plates on the lids (the oily color)

I am pretty sure that the 2" x 2" x 1/8" sq. tube will be bent by the cylinder force. What you guys have? 1/4" or thicker? and the plates I have are 1/8". Should I make them 1/4"?? Obviously weight is our enemy on the FEL, I do not want to put anything more than I need. Like this the whole grapple is 432lbs (mostly made out of 3/8" steel). What do you guys have on your grapples plz?

I am one step before fabricating this monster. I think everything else is fine (well, in theory at least! )

)

And did some FEM analysis, and revealed that I need to tweak it a little bit.

The only place that I am stuck and cannot analyse due to my software's limitation is the lid. Can anyone help me with his experience? What should be the thickness/size of a) the square tubing on the lid where the cylinder rod pushes? b) the thickness of the flat plates on the lids (the oily color)

I am pretty sure that the 2" x 2" x 1/8" sq. tube will be bent by the cylinder force. What you guys have? 1/4" or thicker? and the plates I have are 1/8". Should I make them 1/4"?? Obviously weight is our enemy on the FEL, I do not want to put anything more than I need. Like this the whole grapple is 432lbs (mostly made out of 3/8" steel). What do you guys have on your grapples plz?

I am one step before fabricating this monster. I think everything else is fine (well, in theory at least!