Chris2

Bronze Member

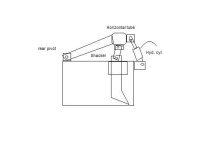

Does anyone have any ideals on using a ram to operate the scarifying teeth on a box blade? I did a search and only found one that used a ram to operate gear driven teeth, it looks very nice but probably more than I can build myself.

Could I weld the top of the teeth to a heavy piece of flat bar with a short A-frame (to spread the load) welded to the top of the flat bar and use a ram to move the teeth.

Any advice would be helpfull, thanks

Could I weld the top of the teeth to a heavy piece of flat bar with a short A-frame (to spread the load) welded to the top of the flat bar and use a ram to move the teeth.

Any advice would be helpfull, thanks