dfkrug

Super Member

- Joined

- Feb 3, 2004

- Messages

- 7,177

- Location

- Santa Cruz Mtns, CA

- Tractor

- 05 Kioti CK30HST w/ Prairie Dog backhoe, XN08 mini-X

Here is another of my full custom backhoe subframes....this time

for a Kioti CK30. This one was my hardest and most ambitious so far.

I have now done full custom subframes for an L2500, two JD 955s (2

diff kinds of subframes), a CK30, and a factory old style subframe from

Woods for an L2550.

A goal for this project was first to get the best subframe I could

do for this tractor. Not all the best criteria were compatible, however.

e.g. the quickest attachment method may not be the tightest. Anyway,

after building a few different kinds of frames and carefully evaluating

factory frames, I decided on this implementation. I have modeled my

subframe after the tightly-coupled frames you may see on a small

commercial-duty machine like the L39 or even a larger CASE 580. Mainly

this means a "4-pt" attachment with some sort of alignment aid at

the lower section of the subframe. The hoe is tilted into the lower

part and secured with bolts or pins at the top. I went with bolts, since

they allow less wiggling. Professional machines also mount the hoe as

close as possible to the back of the tractor. I have done this, too.

There is no use of the 3-pt bracket to secure the hoe. Finally, I

wanted the 3-pt arms to not have to be removed when the hoe is

mounted.

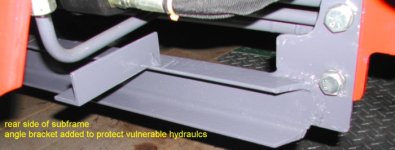

The CK30 was tough to do, due to all the exposed hydraulics underneath.

Now they are pretected!

These pix are the results. There is no detectable wiggle or flex, I

am happy to report.

I may try one of Woods' new 4-pt frames for another Kioti this summer.

Then I will have more to compare it to.

for a Kioti CK30. This one was my hardest and most ambitious so far.

I have now done full custom subframes for an L2500, two JD 955s (2

diff kinds of subframes), a CK30, and a factory old style subframe from

Woods for an L2550.

A goal for this project was first to get the best subframe I could

do for this tractor. Not all the best criteria were compatible, however.

e.g. the quickest attachment method may not be the tightest. Anyway,

after building a few different kinds of frames and carefully evaluating

factory frames, I decided on this implementation. I have modeled my

subframe after the tightly-coupled frames you may see on a small

commercial-duty machine like the L39 or even a larger CASE 580. Mainly

this means a "4-pt" attachment with some sort of alignment aid at

the lower section of the subframe. The hoe is tilted into the lower

part and secured with bolts or pins at the top. I went with bolts, since

they allow less wiggling. Professional machines also mount the hoe as

close as possible to the back of the tractor. I have done this, too.

There is no use of the 3-pt bracket to secure the hoe. Finally, I

wanted the 3-pt arms to not have to be removed when the hoe is

mounted.

The CK30 was tough to do, due to all the exposed hydraulics underneath.

Now they are pretected!

These pix are the results. There is no detectable wiggle or flex, I

am happy to report.

I may try one of Woods' new 4-pt frames for another Kioti this summer.

Then I will have more to compare it to.

Attachments

-

PrairieDog_r.jpg124.6 KB · Views: 3,457

PrairieDog_r.jpg124.6 KB · Views: 3,457 -

CK30_sub_r_1.jpg71.7 KB · Views: 3,623

CK30_sub_r_1.jpg71.7 KB · Views: 3,623 -

CK30_sub_r_2.jpg96.7 KB · Views: 2,910

CK30_sub_r_2.jpg96.7 KB · Views: 2,910 -

CK30_sub_r_3.jpg50.4 KB · Views: 2,619

CK30_sub_r_3.jpg50.4 KB · Views: 2,619 -

CK30_sub_ft_1.jpg89.6 KB · Views: 2,483

CK30_sub_ft_1.jpg89.6 KB · Views: 2,483 -

CK30_sub_ft_2.jpg76 KB · Views: 2,546

CK30_sub_ft_2.jpg76 KB · Views: 2,546 -

CK30_sub_ft_3.jpg72.5 KB · Views: 2,347

CK30_sub_ft_3.jpg72.5 KB · Views: 2,347 -

CK30_sub_mntd_1.jpg47.1 KB · Views: 2,526

CK30_sub_mntd_1.jpg47.1 KB · Views: 2,526 -

CK30_sub_mntd_2.jpg72.9 KB · Views: 2,751

CK30_sub_mntd_2.jpg72.9 KB · Views: 2,751 -

CK30_sub_mntd_3.jpg43.1 KB · Views: 2,546

CK30_sub_mntd_3.jpg43.1 KB · Views: 2,546 -

CK30_sub_mntd_4.jpg133.8 KB · Views: 3,023

CK30_sub_mntd_4.jpg133.8 KB · Views: 3,023