I'd like to add additional emphasis to the idea of extending the gauge wheel(s) farther to the rear than has been done traditionally.

Bigger tractors with longer wheel bases do a smoother job of leveling irregularities, mostly because of the longer wheelbase and longer distance from rear axle to the cutting edge of the box blade. I have a friend with a Land Plane which is pulled with a trailer hitch/ball arrangement and runs on two trailer tires that are raised and lowered hydraulically. It has a fairly long tongue, especially when compared to my box blade. I have worked my tractor and box blade side by side with him and the message was clear, LONG WHEELBASE and LONG TONGUE = SMOOTHER RESULTS!

I have seen the rigs they use in the Imperial Valley in California to produce thousands of acres that are so flat they can irrigate from one end to the other and not have water pool up. Big Cats with very looooooong distances from tractor to blade and blade to rear support/gauge wheels.

Well, we can't adjust the wheelbase of our CUTs or conveniently adjust the distance from 2PH to cutting blade but we can take certain other steps to improve our results in some situations. Gauge wheels are one such step. Gauge wheels mounted well back (and or adjustable in trail distance) will allow a short wheelbase tractor with a standard box blade to perform almost as if it were a BIG LONG WHEELBASE tractor with a long reach to the cutting blade.

When you run over a "WHOOPDEDOO" with a box blade on a CUT you often do not improve it and might make it worse or just relocate it. If you go really slow and have TNT and are good with it you might do a bit better but it is a lot of fussing for a little work. Trailing gauge wheels help "AVERAGE" out the whoopdedoo. A greater trailing distance averages the blades cutting action over a longer distance which can be a good thing and when it isn't you can easily move the adjustable trailing gauge wheel(s) to a shorter trailing distance.

I would recommend considering two gauge wheels. If for some reason you need the effect of one wheel, raise one out of the way. If left to right location is a factor, you could make that adjustable too.

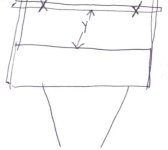

In the attached sketch (that reveals my lack of talent) the X's mark the location of gauge wheels, adjustable side to side. The Y distance is adjustable too. The converging lines at the bottom of the sketch are the arms of the 3PH and they attach to the rectangle which is the box blade.

Pat