Have been having problems with a Branson 3510 PTO that has baffled several highly experienced tractor users. The Tractor is 9 years old and have had it since day 1. Recently, the PTO started shutting off while mowing and after replacing the fuse seemed to work. Then it shut down again while mowing. This was intermittent at first then became very frequent. I wound up replacing the PTO switches (both front and rear) and thought it was fixed then it shut down again. I then inspected the fuse block and found minor corrosion on the terminals so I cut the leads and installed a separate fuse block for the PTO. Now everything electrical has been replaced. Trying to determine if there is a coil or some relay that could be causing the problem. The manual is not clear enough to trace all components. I did take it to a dealer and put it on a servo to test the mechanical components and everything mechanically seems fine. Anyone out there have any suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-Point Hitch Branson 3510i PTO problem

- Thread starter reverett

- Start date

/ Branson 3510i PTO problem

#1

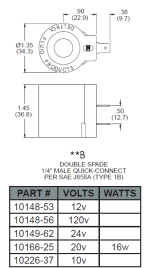

I was able to fix this problem with a PTO coil that is not listed as a separate part in the manual. Dealers want over $200. to replace the coil. The part is made by Deltrol Fluid Products, Manufacturers part # is 10148-53 very easy to replace if you catch it before it melts to the shaft. ( the outer housing is bakelite plastic and the inner sleeve is metal). Available online from Motionindustries.Com for around $20. plus shipping. their item number is 04762025

psyched123

Member

View attachment 477078

I took off the rear wheel and removed this coil. Is this the coil that you bought for $20? Thanks!

That's it. But the replacement comes with 2 spade terminals that will require you to cut the wires off the old coil (as close to the coil as possible so you don't shorten the lead) and put 2 female crimp connectors on then you can connect to the spade terminals on the new coil. Does not matter which wire you put on either spade terminal.

psyched123

Member

Great! I'll let you know when I'm successful and back out in the field mowing.

psyched123

Member

I just to this in from Motion Industries.

I just to this in from Motion Industries. "Lynn,

Here is a drawing of the Deltrol 10148-53 1/2"id coil to see if the dimensions match up. It does not appear to be the same shape as the one you have in the picture, I cannot say if it will work or not. "

It does look a little different in shape. Sure it will fit?

View attachment 477092I just to this in from Motion Industries.

"Lynn,

Here is a drawing of the Deltrol 10148-53 1/2"id coil to see if the dimensions match up. It does not appear to be the same shape as the one you have in the picture, I cannot say if it will work or not. "

It does look a little different in shape. Sure it will fit?

They are different in shape but are the same functionally. Here is that part installed on a Branson 3510 2 years ago that uses the same coil as the branson 3820. The one I took off originally is identical to the photo sent earlier. Disregard the brass air fitting in the photo it's the only nut I had that would fit the shaft when the original stripped.

View attachment 477093

They are different in shape but are the same functionally. Here is that part installed on a Branson 3510 2 years ago that uses the same coil as the branson 3820. The one I took off originally is identical to the photo sent earlier. Disregard the brass air fitting in the photo it's the only nut I had that would fit the shaft when the original stripped.

I removed the coil from the tractor so you can see the difference in the original and replacement. They look different by function identically. When I removed the coil I noticed it was necessary to add bushing or washers to make up the difference for length. But it works just fine and cost $20. instead of over $200.

Tried to get the part number but with the corrosion it's hard to make out.

LincTex

Silver Member

Reverett, how did you troubleshoot to determine it was the solenoid coil that needed to be replaced?

Reverett, how did you troubleshoot to determine it was the solenoid coil that needed to be replaced?

It was basicly trial and error. I, as others have posted, only experienced the problem after mowing an hour or so. Then the PTO would shut off and the light on the dash would be off. I'd check the fuse and sometimes it would be blown and sometimes not. The switch seemed to be the culprit although it tested fine with an ohm meter but I replaced it anyway (anyone want to purchase a perfectly good used PTO switch?). As the problem became more frequent the more often it appeared to be a thermal issue. When it would cool down I could get it going again. I took it to 2 different Branson dealers and explained the issue. One said that the fuse block may be having corrosion issues that could be causing the problem when hot. So I tapped it to the fuse block, removed the PTO from the circuit and put it on it's on fuse block. No help. I then bypassed the wires in the harness to the switch with a new wires. No help. Took it to the second dealer and explained what was happening and what steps I had taken to correct it with no luck. He thought it might be the coil and explained that Branson does not list the coil as a separate part but was only included in the pump assembly and ran about $800-$900 to replace but he had an alternative 3rd party part for replacing the coil. He first tested the coil and said it seemed ok but it was cold when he tested it. The next time I used the mower it stopped after about 15 min and could never get it going again. Before, when it would cool down or sit overnight it would work again but this time it would not. So, I called the second dealer back, purchased the coil for $50 and was a non Brason part. As far as I can tell Branson does not have a part number for this item (the other Branson dealer wanted over $200. after he researched and found the part 3rd party).

When I went to remove the old coil I had to pry it off the stud that it mounts to. It should just slide off with little effort. The internal plastics had heated to the point of melting causing it to weld itself to the stud. I guess with so many failures and attempts to correct it finally just fried. It also caused the mounting nut which was a hard plastic to strip. This nut has a flange and is not a standard nut. That's why in the previous photo you see an air fitting adapter holding the coil in place and since I didn't have the flange like the original nut I added a washer and neoprene spacer so the coil would be snug. the air adapter is the only thing I had that would fit the diameter and threads on the end of the stud. It does not need to be torqued down but just tight enough so it won't back off during usage. The original flanged nut was a self lock nut.

Now, I think this part will require a washer 1/16 or 1/32 thick with 1/2" diameter hole to be placed between the nut and outside of the coil to make up the slight difference in the length of the coil. It's been 2 years since I did this repair and can't remember every detail. Now with all that said, when I got the coil replaced my troubles were over. I made sure I had the manufacturers part number recorded in my manual for future use and is included in my previous post along with a web site to purchase for less than I did..

What I learned through about 2 months of trouble shooting and trial and error is that when you turn on the PTO switch it keeps a constant 12v, 16watt current at the coil. The coil acts a a solenoid to push a plunger in to activate the pump. With age, that coil will start to be affected by temperatures and will fail when hot. The more often this failure occurs the less time it will take to fail again. The first time mine failed it was 5 or 6 months before it failed again and then became more frequent as in failing every time I tried to mow. It first failed in the summer of 2013 and completely died in the summer of 2014. After replacing the coil it has not failed since and I've put over 150 hours on the tractor since then.

Last edited: