Diamondpilot

Super Star Member

- Joined

- Jan 18, 2007

- Messages

- 16,326

- Location

- Daleville, IN

- Tractor

- Jinma 254/284 Ford 861 Powermaster at work

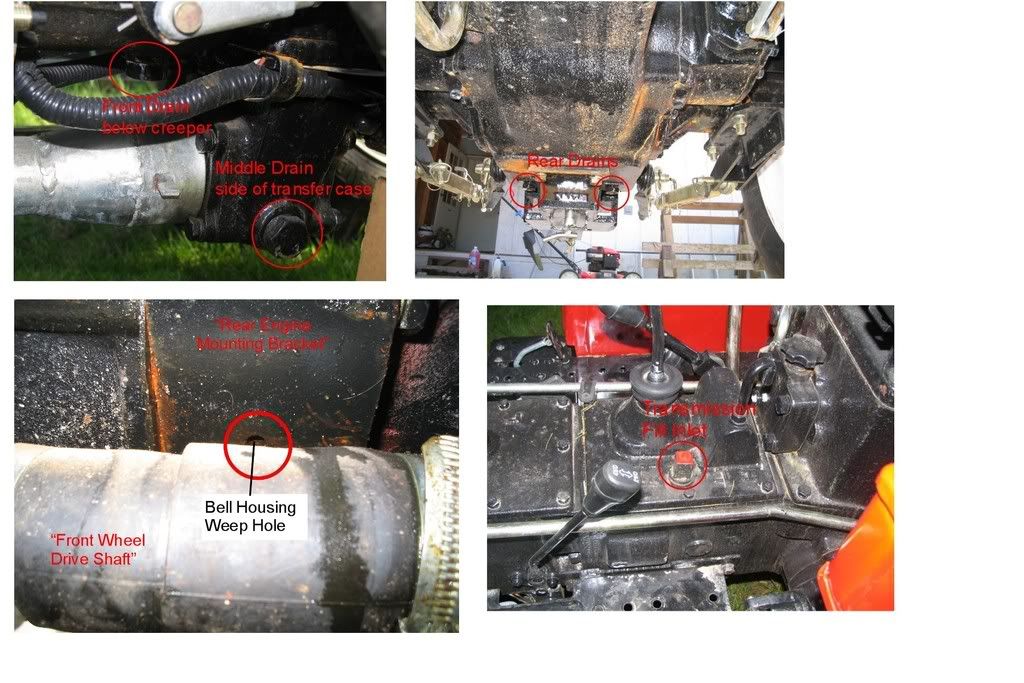

Didn't open up the transfer case yet but I figured out the trick to move from 4 to 2 to 4 wheel drive. Just like everyone here said you have to have the tractor crawling a bit with the clutch in and it will shift very easily! Now I did some more mowing here with the unit in 2 wheel drive and I still heard the rattle or clunk just below me but not as frequent; more noticeable on a bumpy area. It is also there without the PTO driven which I remember as well. I'm now thinking worst case scenario that something is loose in there and I've been lucky so far. I'm not sure where to open up the unit yet but I'll have a closer look now. Any pictures or explanations would be much appreciated as always.

Thanks

Cory

If you have a FEL check its connections out. Especially the area where the loader arms are in the saddles of the loader mount. There is a piece of threaded rod that may need snugged up. Its where the pin goes though and then the rod is snugged up to take up the slack. Mine will tell me when they are working lose.

Also, I do not use the clutch when going from 2 wheel to 4 wheel drive. I just put a little pressure on the control and it slides right in and out when the tractor is in motion.

Chris