RonMar

Elite Member

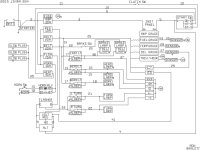

In troubleshooting my tach failure (bad sensor, only putting out .5V signal instead of the nearly 5V signal the tach needs to operate) I pulled my cowling and also did some wire cleanup. This gave me the chance to finally finish the updated electrical schematic I started several years ago, which I have attached here.

Enjoy!

Enjoy!