chris85

Bronze Member

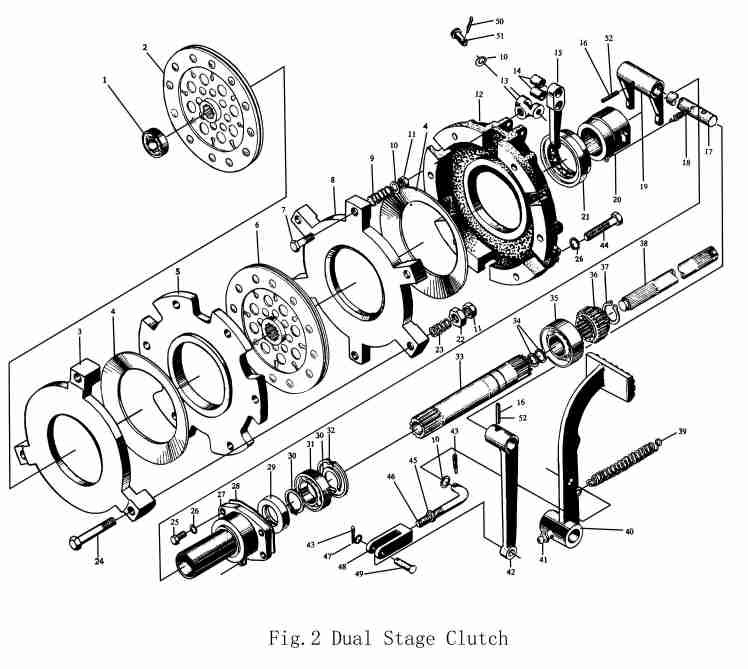

Ok. Might not be serious. But you'll have to drop the loader mounts to get at the clutch inspection windows. Well, at least one of them anyway. Once you can see inside, rotate the clutchpack a full 360 degrees so you can get a look at all 3 release fingers. They're supposed to each be 2.5mm (+/- 0.5mm) away from vertical face of the throwout bearing. Not too much tolerance allowed either, as they should be +/-0.1mm of each other when finished adjusting. If they're all already within the 0.1mm, you can make the adjustment outside. It's done by adjusting the pull rod Y-collar one direction or the other. But if they're uneven, that has to be fixed first - before you adjust the pull rod length. In some cases the stop bolt must be adjusted as well.

//greg//

Did you by any chance see my other post..

"Off of the clutch pedal there is a link arm attached to a spring, the link arm attaches to a rod that slides over a shaft that comes out of the tractor. The bolt holding this rod to the shaft was broke clean off so I assumed this may be the issue as it looks like this shaft should turn when the peddle is pushed. I replaced the bolt but the shaft does not move at all."