I recently purchase a Jinma 254 and a few things needs to be done to bring it back to optimal condition.

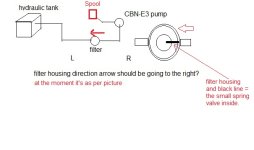

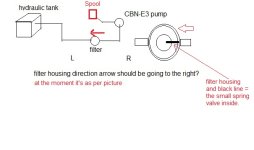

Question 1. The first thing I did is dump all fluids new filters and the problem I知 having at this point is the hydraulic leaking not performing right. so I ordered a new pump and seals to rebuild the old one for a spare and one of my concerns is when you remove the hydraulic pump you lose your hydraulic and once I will install my new pump I need to know if I need to prime the lines prior or should the new pump pull hydraulic fluid from the reservoir tank in time not to overheat the new pump and seals?

Question 2. I have is the oil pressure sender sensor has 2 connections and only a purple wire is connected to the sender and my oil pressure gauge is reading high almost to 10 and when I disconnect the purple wire the gauge still stays to 10, the only time the gauge goes back to zero is when I shut off the engine any chance one of you current owner could take a picture of the color wires going to the sender?

Question 3. Very similar question as above but for my engine temp sender wire was cut off and I知 looking for the correct color wire that should have been used.

Thank you very much to all that can help me

Question 4. This is from my own lack of knowledge 都tupidity before I decided to remove the hydraulic pump slow leak I notice the loader when I was trying to get a good load I would have to bring up the idle and I read online to correct this to simply adjust your spool relive valve that allen key way threaded screw down a few turns and guess what it worked for the first time I was able to use my buck to lift up the tractor and 5 minute later all my hydraulic system stop work? O did I ever want to kick myself in the *** on that one because from what I read after this is those relive valve are usually preset and most likely the reason the bucket was not lifting up the buck front end loader was due to a weak hydraulic pump this is why I decided to order a new pump and new sender sensor / engine thermostat etc .

I thank everyone in advance for any help because I sure do need it purchase this tractor because I had major back surgery last year and want to start using a tractor to do the heavy lifting around the house instead of my back

Question 1. The first thing I did is dump all fluids new filters and the problem I知 having at this point is the hydraulic leaking not performing right. so I ordered a new pump and seals to rebuild the old one for a spare and one of my concerns is when you remove the hydraulic pump you lose your hydraulic and once I will install my new pump I need to know if I need to prime the lines prior or should the new pump pull hydraulic fluid from the reservoir tank in time not to overheat the new pump and seals?

Question 2. I have is the oil pressure sender sensor has 2 connections and only a purple wire is connected to the sender and my oil pressure gauge is reading high almost to 10 and when I disconnect the purple wire the gauge still stays to 10, the only time the gauge goes back to zero is when I shut off the engine any chance one of you current owner could take a picture of the color wires going to the sender?

Question 3. Very similar question as above but for my engine temp sender wire was cut off and I知 looking for the correct color wire that should have been used.

Thank you very much to all that can help me

Question 4. This is from my own lack of knowledge 都tupidity before I decided to remove the hydraulic pump slow leak I notice the loader when I was trying to get a good load I would have to bring up the idle and I read online to correct this to simply adjust your spool relive valve that allen key way threaded screw down a few turns and guess what it worked for the first time I was able to use my buck to lift up the tractor and 5 minute later all my hydraulic system stop work? O did I ever want to kick myself in the *** on that one because from what I read after this is those relive valve are usually preset and most likely the reason the bucket was not lifting up the buck front end loader was due to a weak hydraulic pump this is why I decided to order a new pump and new sender sensor / engine thermostat etc .

I thank everyone in advance for any help because I sure do need it purchase this tractor because I had major back surgery last year and want to start using a tractor to do the heavy lifting around the house instead of my back