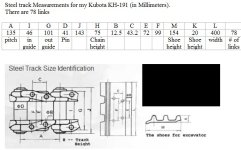

cheezomlet said:

I need to replace the 400mm STEEL tracks on my KH-191. I see they have rubber tracks available so here are my 3 questions:

1, If I get the rubber tracks, do I need to convert any of the undercarriage? (beside the obvious worn parts)Nobody seems to know this answer, not even my local Kubota dealer

Simply yes, you will be going from a SALT ( Sealed and Lubricated metal track) and if it is dry pin designed how do you stand the noise, to a soft track held together with rubber straps, plates with fasteners. Your carrier bearings will have to be changed to Bogey wheels usually foam filled rubber tires on rims, Urethane sprockets on the drive planetaries and a different style track tension cylinder torque arm assembly. Good luck converting for the same price of the OEM steel track replacement. If your pads or grousers have 1/2 life considered rotating you bushings and resealing your pin with new seals and fresh lubicant on a track press. I want you to understand I have never swapped designs on a Kubota Excavator but have experience with Komatsu, CAT, Deere and Camoplast, Cental Mine Equipment, and Softtrack rubber tracks with my rental fleet. We mount digger derricks and aerials on rubber tracks for Contractors and Utility Companies US wide. It is not cheap to maintain rubber track designs. They require about double the maintenance to Steel. Google Itialian Companies for your new steel tracks. You might be pleasantly surprised with pricing but watch your rockwell ratings with the DIN stardards for hardness.

Maybe it's an American thing - but over here in Europe, the changes described by

ob1kubota simply aren't necessary. Generally most excavators under 13 tonne can be fitted with either rubber or metal tracks, with no substantial change to the running gear or undercarriage.

Also rubber tracks are not as described above

- "a soft track held together with rubber straps, plates with fasteners." Sounds to me like ob1 is thinking more of some kind of s&m device! Rubber track technology has come on leaps and bounds in recent years providing longevity and strength at a fraction of the cost of metal tracks. I do agree however that the maintenance on a rubber track will be slightly greater - they will require replacing more often than metal, and tend to need tensioning on a more regular basis.

At the end of the day it is down to personal preference, and worksite conditions - here in Spain we are on rubber tracks as we do a lot of work in peoples gardens, and the rubber causes less damage to driveways / patios / paths etc. However my personal preference here would actually be metal, as the rocky terrain shreds our tracks in about 12 mths.

Finally take a look at the

Dig Bits Website for more info on rubber tracks. It is a British company, but they ship to Spain very cheaply, and might also ship to America if you ask them nicely! ****