ford96

New member

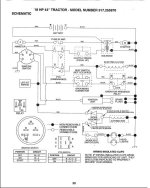

Hi, my cousin has this craftsman lt 1000 tractor with I think a 22horse briggs or maybe a Kohler (not 100%) motor and hydrostatic transmission. The problem is, is the ignition is screwed up it broke apart and can't find a serial number or anything on the tractor that can give sears the right info for a replacement ignition switch and we're country folk we don't care about looks so I was going to wire him a home made ignition setup, I ran a power wire for the starter on a toggle switch but need to figure out the ignition wire that will allow the motor to run and stay running. If anyone has any idea how to make it work from here let me know. Thanks  If you need to know the exact motor I will find out.

If you need to know the exact motor I will find out.