Grayson Klassen

Gold Member

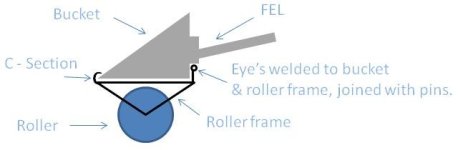

I have a tow behind roller that is 5 feet wide. I want your guys opinion on modifying it so instead of filling it for weight I can attach it to my FEL and push down on it.

The biggest reason I want to do this is lack of turn around room when I am rolling roads

What do you think let me have it both barrels

The biggest reason I want to do this is lack of turn around room when I am rolling roads

What do you think let me have it both barrels