srs

Veteran Member

With the ball on top of the bucket, I couldn't get it under the coupler of my trailer. I use a ball mount with 6" or so of drop. Also, the 2" receiver tube leaves the mounting location open for other uses, should they arise.

Joshuabardwell, if you look at one of the three pictures I posted earlier in this thread you'll see how I made a drop type ball hitch to move my trailer around. It really works nice. I did have to reinforce it cause I was able to bend the steel with my 16' utility trailer.

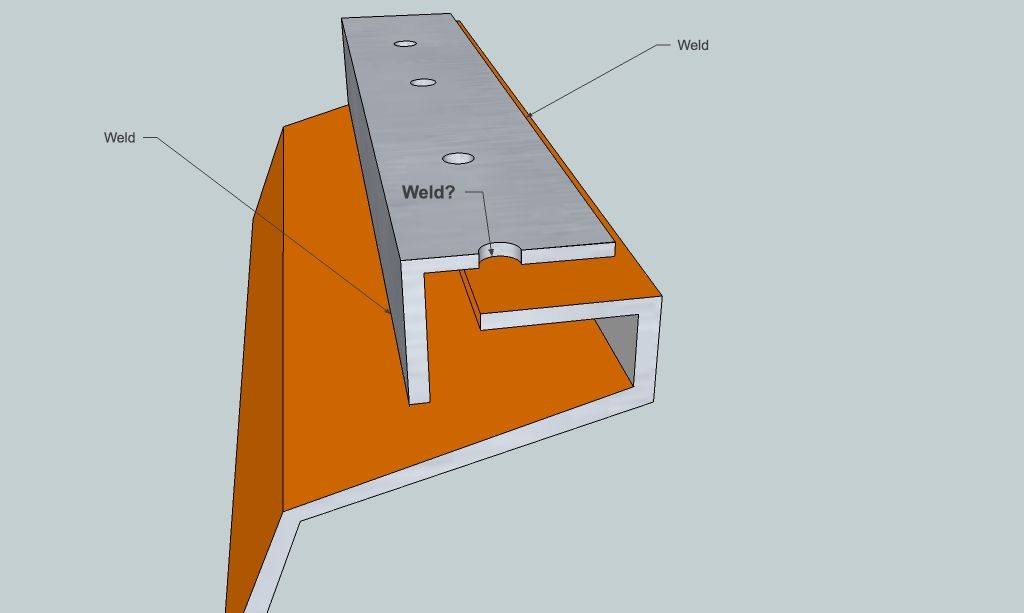

Teikas Dad, that is exactly what I used, again see my pictures in this thread.Based on what everyone has suggested I'm going with a 3X3 piece of angle mounted on the back of the lip like this.

The top flat portion of the 3X3 will stop about 1/4 inch or so before the radius of the bucket lip downturn starts so I'll have enough space to run some beads. The back/lower leg of the 3X3 will hit the back of the bucket about half way between the lower radius and the back edge of the top lip. A bunch of weld beads along there will hold that together and make a box. The flat top of the 3X3 will give me a good surface to weld the hooks on to.

I appreciate all the input!