jeffgreef

Silver Member

- Joined

- Jul 20, 2009

- Messages

- 189

- Location

- Plumas County, California

- Tractor

- Farmall, Gibson, Windolph, Simar, Bear Cat, Vaughan, Howard

I just discovered that my 1950 Super A does not have a magneto- battery ignition was an option offered by Int. at this time.

Still haven't figured out what I need to do to do a proper 12 volt conversion- appreciate it if someone can give me a rundown on the basics. I'll probably do a rewire too.

Photo shows the dist. and coil, and a mystery box wrapped in tape coming off the coil. What is that little box?

A 6 volt alternator was connected to the unit some time ago.

thanks for your time. I hope all these questions I'm asking are instructive for other Super A owners.

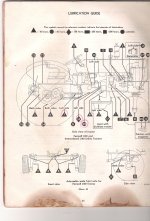

Edit- also- what is that little screw on the distributor mount, 2 inches below the center of the coil? Is this a lube point?

Still haven't figured out what I need to do to do a proper 12 volt conversion- appreciate it if someone can give me a rundown on the basics. I'll probably do a rewire too.

Photo shows the dist. and coil, and a mystery box wrapped in tape coming off the coil. What is that little box?

A 6 volt alternator was connected to the unit some time ago.

thanks for your time. I hope all these questions I'm asking are instructive for other Super A owners.

Edit- also- what is that little screw on the distributor mount, 2 inches below the center of the coil? Is this a lube point?