Ford851

Bronze Member

Hello Ford851 again,

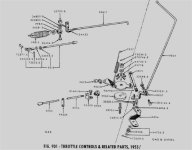

I was happily putting my tractor (Ford 851) back together and put in the gas control lever, tightened it down, and it would not turn. So removed the battery box and found a plate of some sort. Seeing that it was dirty and crusty I tried to undo the bolt in the center holding it down to the tractor. The whole stud came out to the top of the tractor housing. Oh, great.

This thing looked like it needed some serious attention. So I thought I would take the bolt out of the center, but couldn't. I oiled where it rotated around the stud. Put grease on upper and lower side of the pad and cleaned the flat part on top of the tractor housing. Then put grease on the housing and put the assembly back together.

It turns, so I hooked the linkage back up.

But I have the sinking feeling something is wrong and I've missed it. It still looks bad because I can't get the castle nut to release from the center stud (the whole stud turns) and that spider looking on top is still not looking terrible.

What is the purpose of this gizmo and how is it suppose to function?

Thanks in advance,

Ford851:confused2:

I was happily putting my tractor (Ford 851) back together and put in the gas control lever, tightened it down, and it would not turn. So removed the battery box and found a plate of some sort. Seeing that it was dirty and crusty I tried to undo the bolt in the center holding it down to the tractor. The whole stud came out to the top of the tractor housing. Oh, great.

This thing looked like it needed some serious attention. So I thought I would take the bolt out of the center, but couldn't. I oiled where it rotated around the stud. Put grease on upper and lower side of the pad and cleaned the flat part on top of the tractor housing. Then put grease on the housing and put the assembly back together.

It turns, so I hooked the linkage back up.

But I have the sinking feeling something is wrong and I've missed it. It still looks bad because I can't get the castle nut to release from the center stud (the whole stud turns) and that spider looking on top is still not looking terrible.

What is the purpose of this gizmo and how is it suppose to function?

Thanks in advance,

Ford851:confused2: