shealray

New member

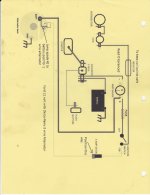

You asked for a picture of my tractor so others could learn from my experience with it.

The most valued experience I have learned is 鉄haring ideas? the willingness too

help a stranger with a problem is a gift for the heart. My wish is for this gift of sharing always

be given from the heart.

My gift is what I learned about wiring the little Ford 850 tractor.

Thank you for your kindness in sharing

The most valued experience I have learned is 鉄haring ideas? the willingness too

help a stranger with a problem is a gift for the heart. My wish is for this gift of sharing always

be given from the heart.

My gift is what I learned about wiring the little Ford 850 tractor.

Thank you for your kindness in sharing