You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model L and Model C Repower Parts

- Thread starter gravelymay

- Start date

/ Model L and Model C Repower Parts

#1

OP

gravelymay

Gold Member

Repower to 1 inch crank Engine parts :thumbsup:

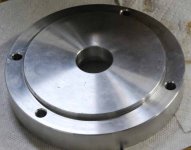

This gear can be used for repowering the L Model C8 & C10.

It is made for 1 inch dia crank shafts 3.3/4 long

also can be used on 3.00 long crank shafts

For repower over head engines.

Here are some better pictures.

Thanks Bruce g

423 716 4611

Attachments

OP

gravelymay

Gold Member

Hi Guys

I though I would pass along a repower on a 5665

That Bob did and wrote it up as he done it.

Best write up I have ever saw.

http://tinyurl.com/4jvm938

Thanks Bruce g

I though I would pass along a repower on a 5665

That Bob did and wrote it up as he done it.

Best write up I have ever saw.

http://tinyurl.com/4jvm938

Thanks Bruce g

2manyrocks

Super Member

- Joined

- Jul 28, 2007

- Messages

- 7,297

That's the best one I've seen, also.

hawkeye08

Elite Member

Very nice job and very nice write up!

OP

gravelymay

Gold Member

Here is a LI Frankenstein That I put a 13 Hp Honda on .

Runs out good :thumbsup:

But the wheels are to close to the deck.

It don't have a remote control lever for the PTO.

The forward & reverse lever is backward to me.

I plan to fix all three.

Thanks Bruce g

423 716 4611

Runs out good :thumbsup:

But the wheels are to close to the deck.

It don't have a remote control lever for the PTO.

The forward & reverse lever is backward to me.

I plan to fix all three.

Thanks Bruce g

423 716 4611

Attachments

Bret4207

New member

- Joined

- Jul 8, 2005

- Messages

- 24

- Location

- St Lawrence Valley NY

- Tractor

- Ford, JD, Case, Cockshutt, David Brown, Gravely, Simplicity, Wheel Horse

Bruce, this is very interesting. The cost of Gravely parts is simply obscene these days. My only concern is that we'll have the same problem with the modern engines as with the Kohlers- the PTO speed is too fast for the implements like the sickle bar and even the rotatry plow. Any ideas on a way to reduce the PTO speed?

oldmech

Gold Member

- Joined

- Dec 26, 2006

- Messages

- 468

- Location

- Quebec

- Tractor

- Two Gravely Two L One with 10 h.p Dek-Diesel engine one Grillo 107d and one BCS 735 diesel

HI! With Gravely L model we have two PTO speeds In low range engine speed 2400 rpm give about 800 rpm PTO and for 2800 rpm engine we have 1000 rpm speed. In high range for 2000 rpm engine PTO rpm is 1000 rpm and for 2800 engine rpm PTO is about 1400 rpm. I use a Gravely L model with reduction gear wheels My 10 hp diesel can turn 3600rpm I never use this speed. I run it at about 2400 rpm because this is (as near all engine) the maximum torque engine speed. More engine speed take more fuel and give less torque. We cannot use modern engine at less 2000rpm. 2400 is the minimum for me. I use my Gravely with rotary plow at 2400rpm with no problem. I dont know the sickle bar but I think Me be you must use the low range. Good luck! Oldmech

Bret4207

New member

- Joined

- Jul 8, 2005

- Messages

- 24

- Location

- St Lawrence Valley NY

- Tractor

- Ford, JD, Case, Cockshutt, David Brown, Gravely, Simplicity, Wheel Horse

Oldmech, that's the problem, even with the low range the Kohler PTO speeds are way too fast for the sickle bar and I personally think also for th erotary plow.

oldmech

Gold Member

- Joined

- Dec 26, 2006

- Messages

- 468

- Location

- Quebec

- Tractor

- Two Gravely Two L One with 10 h.p Dek-Diesel engine one Grillo 107d and one BCS 735 diesel

Hi! I think for sickle bar mower.You are right. I am building a special sickle bar mower for my Grillo. With pulleys and belt we can change ratio. I seen many tractor PTO sickle farm mower. The drive pulley from 540 rpm is more large as 10 in. to 8 for the driven. So after belt slipping about 600rpm. Gravely PTO minimum 800rpm is over or too high. I plan about 600 rpm for my special Sickle bar mower. Good Luck! Oldmech