woodlandfarms

Super Member

- Joined

- Jul 31, 2006

- Messages

- 6,137

- Location

- Los Angeles / SW Washington

- Tractor

- PowerTrac 1850, Kubota RTV x900

I am moving this over from the PT section as maybe someone might also have an opinion (JJ, no offense, I just want to make sure I have covered all my bases).

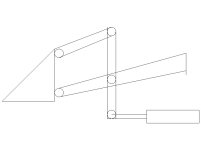

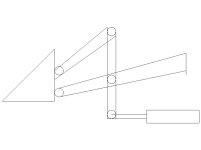

I have a cylinder in need of replacement. It is 20" contracted, 34" extended. I would like it to have a 3" bore and a 1.75" rod. Ideal ends would be 3/4" welded clevis but I will make whatever work.

I have gone through Bailyes and Surplus and all the cylinders are 22" contracted. So, I have 3 choices as I see it.

1 Someone here can suggest where I can get this type of cylinder

2 I can buy the longer cylinder and cut it down (or something comperable)

3 I can remove ears on the tractor and move them to accomodate for the 2" additional lenghth (JJ, you know this tractor, you think I could do this and not mess up the geometry?)

4 - I am missreading the specs at Bailieys and these cylinders are only 20"

Any other sources for HD cylinders? I hate the thought of cutting and welding a cylinder as I know I would mess something up....

Thoughts, comments, generaly derogatory remarks always welcome...

EDIT

JJ, I just thought of something. I wonder if I could put on the 22" cylinder and reduce the rollover by 2" (take it from 20" to 18")

I have a cylinder in need of replacement. It is 20" contracted, 34" extended. I would like it to have a 3" bore and a 1.75" rod. Ideal ends would be 3/4" welded clevis but I will make whatever work.

I have gone through Bailyes and Surplus and all the cylinders are 22" contracted. So, I have 3 choices as I see it.

1 Someone here can suggest where I can get this type of cylinder

2 I can buy the longer cylinder and cut it down (or something comperable)

3 I can remove ears on the tractor and move them to accomodate for the 2" additional lenghth (JJ, you know this tractor, you think I could do this and not mess up the geometry?)

4 - I am missreading the specs at Bailieys and these cylinders are only 20"

Any other sources for HD cylinders? I hate the thought of cutting and welding a cylinder as I know I would mess something up....

Thoughts, comments, generaly derogatory remarks always welcome...

EDIT

JJ, I just thought of something. I wonder if I could put on the 22" cylinder and reduce the rollover by 2" (take it from 20" to 18")

Last edited: