Tried to give a 5 star on video, but mini pincher sits on my shoulders bumped my arm when I clicked, so I guess it is a 4 star!!!:laughing:

Thanx Mmurphy & Akkaman,

There is a way to do a flow test without a flow meter.....I used to do this years ago....

First, take a clean 5 gal plastic bucket and mark it off in 1 gal increments...

Second, set up an external direct acting relief valve at working pressure of your hydraulic system....you may need help from another hyd system or preset at factory.....

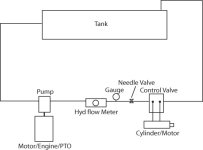

Third, connect a test hose from output of pump to a tee (one end of tee to a needle valve, other end to the preset PRV......

Now here's the fun part......

Have another clean 5 gal bucket right next to marked off one.....

Make sure reservoir is filled.....start tractor with needle valve open(or just open hose ) to unmarked bucket...move oil flow to other bucket at the same time you start timing.....this will allow you to figure your GPM with a stopwatch......Using two buckets will allow you to time it just right.....just have someone to help with the master the on/off switch......

Once you have figured out what the GPM's at 0 PSI, then do the same with the needle valve forcing the flow thru the PRV using the same method.....This will give you approx GPM's at high pressure

Remember, you don't need anymore than idle to show strength of pump and you do not need to fill bucket....only enough to give you an idea of what GPM comes out of open hose or PRV......

Let's say you get 1 gal at 0 psi at 10 seconds........that's 6 gpm's.........use your noodle to figure the ratio of Gals vs Time.......

Then at 2500 psi doing the same test you get 3 gpm's .......That's 50% effenciency at 2500 psi......

Do this test with a cold hyd system, then hook back up everything and warm up hyd oil (sometimes just actuate valve and deadhead against PRV built in to the tractor till it warms up)......then repeat everything with a warm/hot hyd system......See if it's get's worse (it shouldn't)

This is where I draw the line at replacing a hyd pump......50% or less.........

Yes, It'll still work OK (slower but still able to do work) but it's on the way out.....

Then start seeking out rebuild or repair of hyd pump....

If everything checks out then at least you can be confident of your pump....

I'm really surprised that I haven't read here on TBN about this form of test with the 5 gal bucket......but then again that's me