bbutcher

New member

I have a Satoh S650G, a.k.a. "Bison" with a front end loader (FEL). The tractor has a hydraulic system that raises the 3 point hitch. There is a triangular shaped plate under the seat that has two hydraulic lines connecting to the FEL (a pressure line and a return line) control valve. Today I connected my backhoe attachment by adding tees in the lines, so the backhoe control valve is in parallel with the FEL control valve. As connected neither the FEL nor the backhoe operate correctly. It appears that when the control valve for either the FEL or hoe is centered the hydraulic fluid is bypassed from the high pressure line to the return line, thus it never develops pressure enough to operate the cylinders. I assume this is called an open control valve?

If I open any one valve for the FEL, and simultaneously open any one valve for the hoe, both move correctly. As a temporary measure I tied the FEL raise/lower valve in the lower position, and once the FEL is all the way down, the hoe valves work correctly. Likewise I can tie any hoe valve open and once the associated cylinder reaches the end of travel, the FEL works correctly.

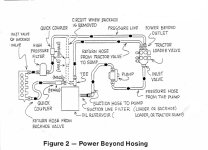

I have heard of a "power beyond" valve (also called "high pressure carry over") that I think will force both systems to work correctly together. I assume that somewhere inside the tractor hydraulic system is something similar since both the 3 point hitch and the FEL work together correctly. In fact the triangular plate mentioned above has 4 o-ring sealed ports, but two of them are just blocked off (never drilled) while the other 2 go to the FEL hoses (pressure and return). Does anyone know if I drilled holes and added 2 more hose connections to the blanked off ports to operate the hoe if this would solve the problem? I found Brendan Casey's description of the power beyond valve, but I don't understand just how to connect it if I found one. Do I need to modify my control valves to make them closed? From what I have read it is necessary to size the power beyond valve for the pump capacity, which is 4.1 GPM for my tractor.

Am I on the right track here, or is there something else I should do? http://www.tractorbynet.com/forums/images/smilies/confused.gif

Bob

If I open any one valve for the FEL, and simultaneously open any one valve for the hoe, both move correctly. As a temporary measure I tied the FEL raise/lower valve in the lower position, and once the FEL is all the way down, the hoe valves work correctly. Likewise I can tie any hoe valve open and once the associated cylinder reaches the end of travel, the FEL works correctly.

I have heard of a "power beyond" valve (also called "high pressure carry over") that I think will force both systems to work correctly together. I assume that somewhere inside the tractor hydraulic system is something similar since both the 3 point hitch and the FEL work together correctly. In fact the triangular plate mentioned above has 4 o-ring sealed ports, but two of them are just blocked off (never drilled) while the other 2 go to the FEL hoses (pressure and return). Does anyone know if I drilled holes and added 2 more hose connections to the blanked off ports to operate the hoe if this would solve the problem? I found Brendan Casey's description of the power beyond valve, but I don't understand just how to connect it if I found one. Do I need to modify my control valves to make them closed? From what I have read it is necessary to size the power beyond valve for the pump capacity, which is 4.1 GPM for my tractor.

Am I on the right track here, or is there something else I should do? http://www.tractorbynet.com/forums/images/smilies/confused.gif

Bob