chad22

Veteran Member

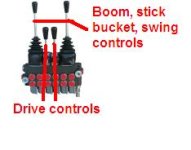

I have another question. I posted that I was rebuilding my backhoe and was gonna use loader joystick valves.

My question is. How do I plumb them both "The loader valves" so that I can use both valves at the same time?

Here's the valve I'm gonna use. Brand Hydraulics Monoblock Loader Valve, Model# PLV22TSTKAB | Control Valves | Northern Tool + Equipment

I want to plumb 2 of those valves to work at the same time.

Thanks

Chad

My question is. How do I plumb them both "The loader valves" so that I can use both valves at the same time?

Here's the valve I'm gonna use. Brand Hydraulics Monoblock Loader Valve, Model# PLV22TSTKAB | Control Valves | Northern Tool + Equipment

I want to plumb 2 of those valves to work at the same time.

Thanks

Chad