I am not sure why you want to use an additional valve to switch fluid flow.

If you have all valves in series, there is no need for the diverter valve in your situation.

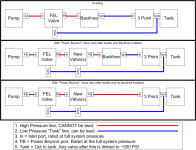

Your flow should be something like this.

Pump , FEL, BH, remotes if you have them or 3pt and tank.

If the BH is connected, you use the loader valve when you have to, or, you use the BH, probably never using both at the same time.

Should you disconnect the BH. then loop a hose from the PB to the remotes or 3pt.

The FEL will have priority over any other valve, and is the master relief for the hyd system.

I might be missing something - because I'm not fully versed on this hydraulic stuff - but:

I believe I have to divert flow.

The FEL is fed from the loader valve block - which has a power beyond port.

That power beyond port goes to the rear of the tractor - to the QD for feeding the backhoe. The other QD on the rear of the tractor - goes directly to the 3pt valve block. The manual shows the 3pt being fed directly from the pump in the case of a tractor with no FEL, being fed directly from the loader valve block in the case of FEL but no backhoe - or lastly (as in the case of my tractor which has the backhoe setup) - being fed from the "return" pipe coming from the backhoe. When the backhoe is not attached - the PB is just looped into the pipe going to the 3pt block.

There is no return piping coming from the 3pt valve block - I believe it dumps internally.

So: I'm not sure how I would get fluid up to the remotes without using a diverter. I suppose I could just plumb another quick connect to the rear of the tractor and swap the hose from the line going to the 3pt - to a line going to the additional front remotes , but I would like to avoid that because it would involve shutting the tractor down - swapping the hose - and the starting the tractor up - to go from using the 3pt or the backhoe - to using the additional front hydraulics.

I have often gone back and forth between using the backhoe - to using the FEL while working. As a matter of convenience I would like to be able to just flip a switch.

I think I understand what you mean about having the valves in series - and I might be missing something - but I don't see how I can put the additional front valves in series - when the end of the line is the 3pt - which appears to dump internally back into the reservoir.

I suppose I could route the flow from the PB forward first - to the additional valves - then route the PB from that back to the backhoe, but I would like to avoid that because it would mean running 3 lines instead of two to the front of the tractor (PB to, PB from, and out) - and it would also put the backhoe and 3pt at the end of a long circuit - which I've got to believe might affect their performance.