memphismark

Bronze Member

Hi guy's.

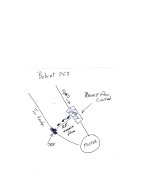

I have a Bobcat 753 that I'm going to use the auxiliary hydro system to drive an auger motor which will drive a shop made 3 yard concrete mixer. I have a Prince RDRS 175-16 flow control valve from Surplus Center to slow the auger from about 50 rpm down to about 25 rpm. I'm new to hydraulics by the way. Anyway, on the motor side return to tank, the hose keeps blowing. I'm not sure what to do. I've heard a pressure spike may be occurring from the motor stopping too fast? Not sure. Maybe some of the smart guys here can give some good advise. Would really appreciate it. Thanks a bunch. Mark

I have a Bobcat 753 that I'm going to use the auxiliary hydro system to drive an auger motor which will drive a shop made 3 yard concrete mixer. I have a Prince RDRS 175-16 flow control valve from Surplus Center to slow the auger from about 50 rpm down to about 25 rpm. I'm new to hydraulics by the way. Anyway, on the motor side return to tank, the hose keeps blowing. I'm not sure what to do. I've heard a pressure spike may be occurring from the motor stopping too fast? Not sure. Maybe some of the smart guys here can give some good advise. Would really appreciate it. Thanks a bunch. Mark